Phenomenon and Vorion are very similar machines and briefly during the NHRL Grand Finals in 2023 they were the same but this year was when the two began to diverge again with innovation being the primary goal (with good and bad results).

Background

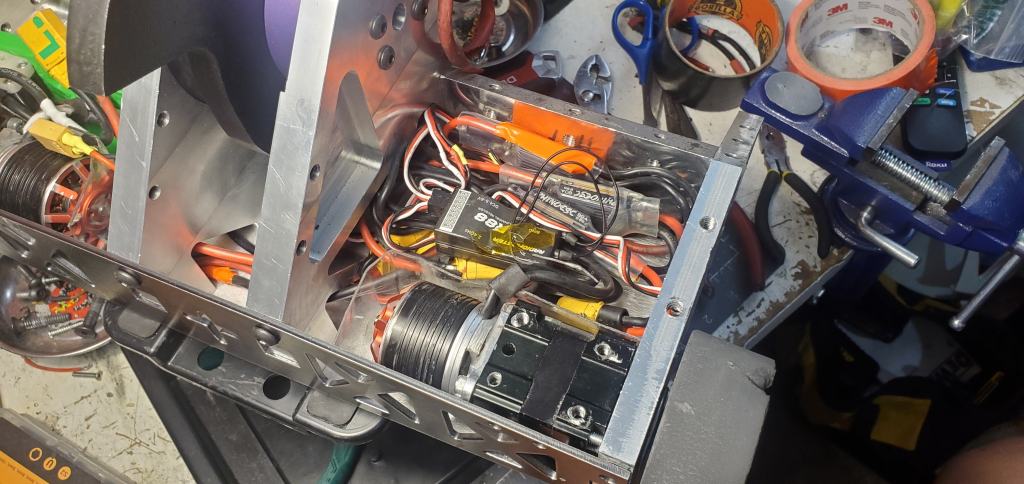

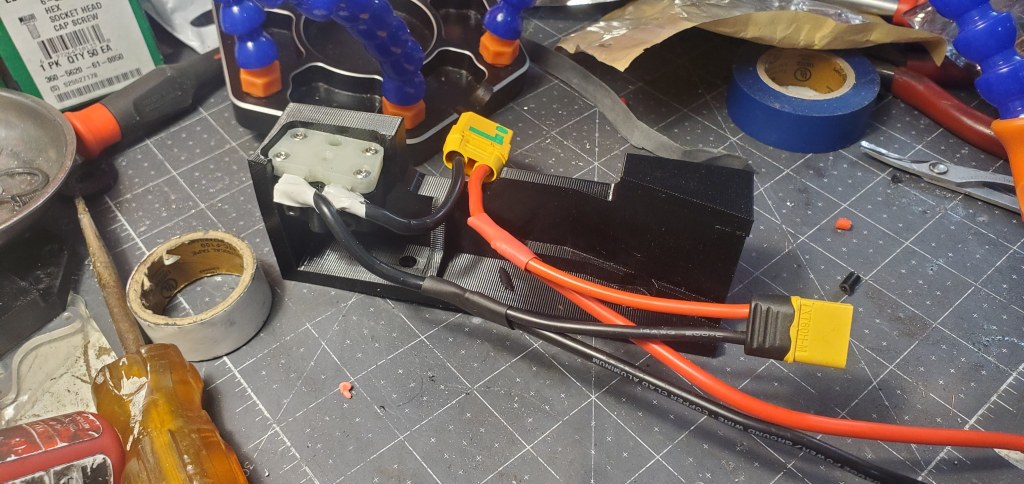

Fundamentally the difference between Phenomenon and Vorion in 2024 is the hubmotor system in Phenomenon. The hubmotor was a direct response to difficulties found in Phenomenon v1 and Vorion’s pulley system. On the internal side, the presence of the motor and ESC inside the right side of the chassis is very space limited. This is very critical due to the left side of the robot being majority space for the battery and power switch to occupy with limited room for the drive ESCs. Initially Phenomenon v1 used the smaller iFlight 80A Blitz ESCs with BLHeli32 firmware. While these controllers were smaller, they lacked the precise control that the later Rhino 80A ESCs with AM32 firmware had. The design of these newer ESCs included a heatsink which further decreased available room inside of the machines and leading to greater concern with electrical issues due to these controllers being under pressure (and did happen here). Finding more area inside of the machine could easily solve this issue.

The external issue with the pulley system was vulnerability to damage. In its fights against any weapon with a larger reach, the aluminum pulley and rubber v-belts were clear targets for attack with hardened steel weapons. Fortunately they were not struck often, but robots such a Knock Off White, Huge, and Emulsifier who all have a greater reach can easily strike the pulley. In addition, due to the high speed and potential for the aluminum to create jagged shapes that cut into the softer rubber, the pulley only needs to be struck once for the belts to be shredded by the weapons’ own energy and lose power entirely. Therefore, the pulley, under certain circumstances, has a very clear failure mode that an opponent can utilize.

The final issue comes with weight. The pulley system’s greatest strength is that there is no fear of the weapon being thrown into even the meanest 30lb spinners. Between Motorama and NHRL, Phenomenon had fought some of the largest horizontal spinners in Big Cookie, Depth Charge, and Floor Letter Word with no weapon issues. Even against the aforementioned weapons that outreach it, a pulley guard was made from welded steel that kept the pulley safe in those matches. Unfortunately, these improvements meant the machine lost much of its flexibility to implement different configurations. In a world where prior preparation is such an essential part of the game, this was a annoying hindrance. As a result of these issues, a new idea was tried: a hubmotor.

Hubmotor

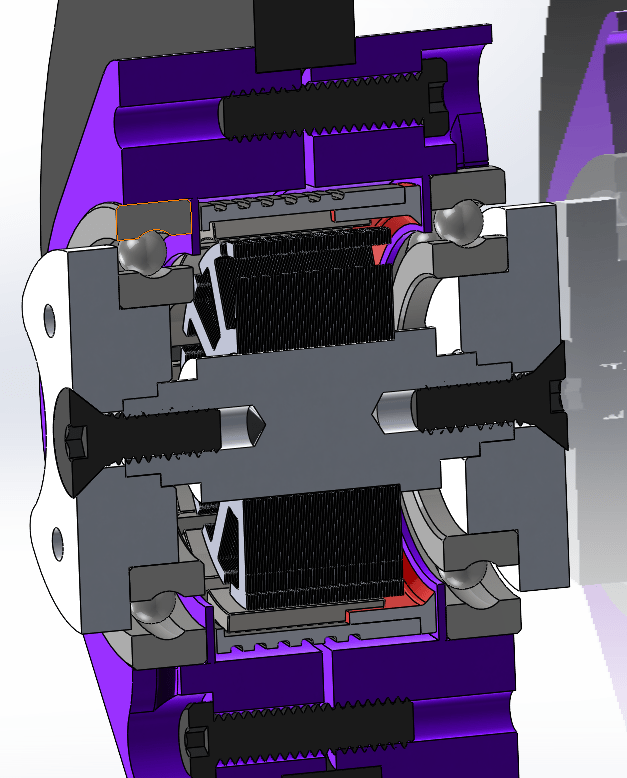

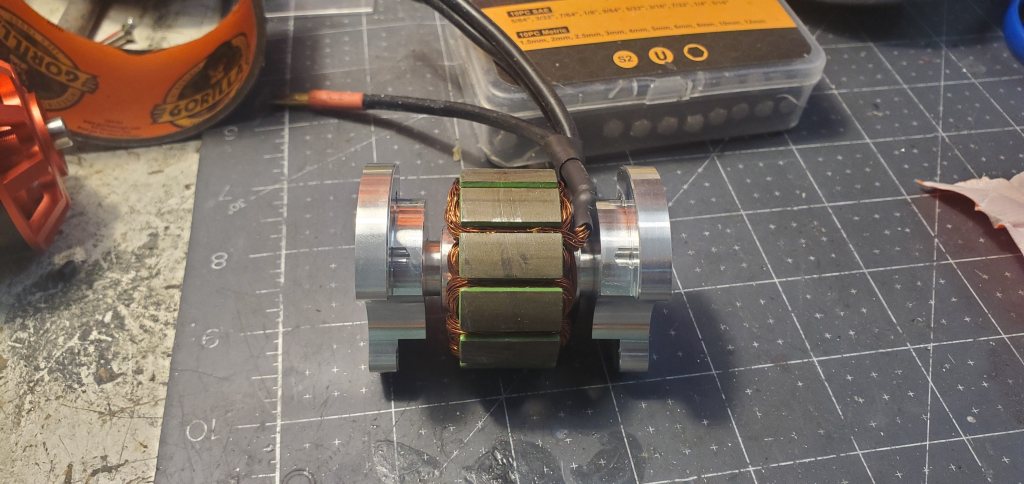

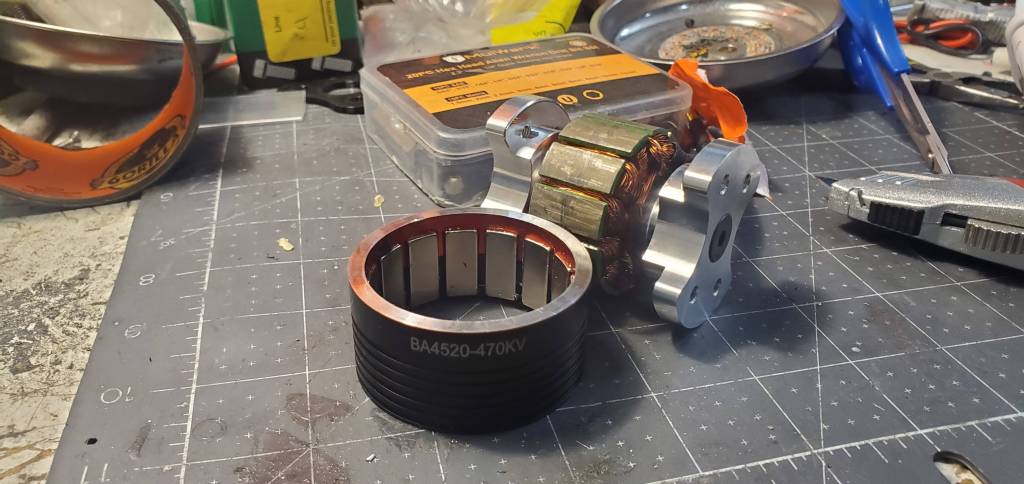

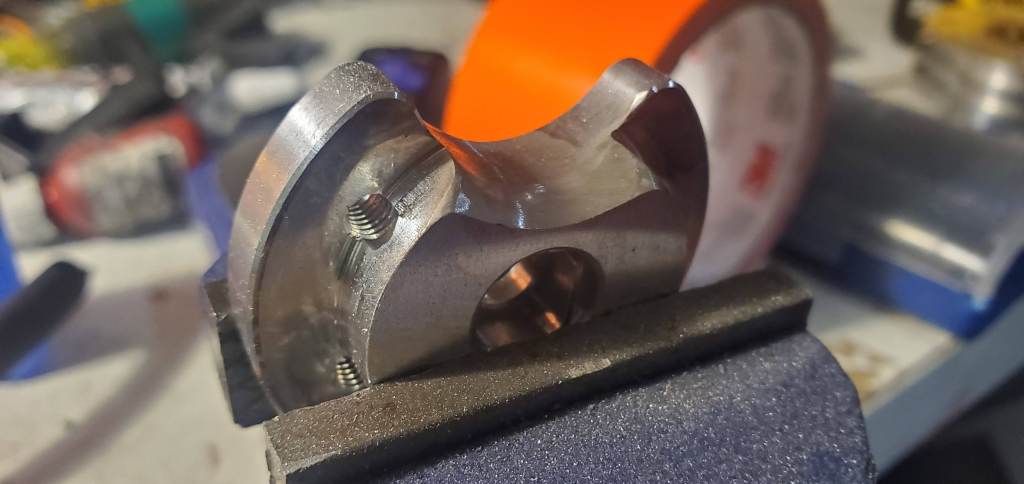

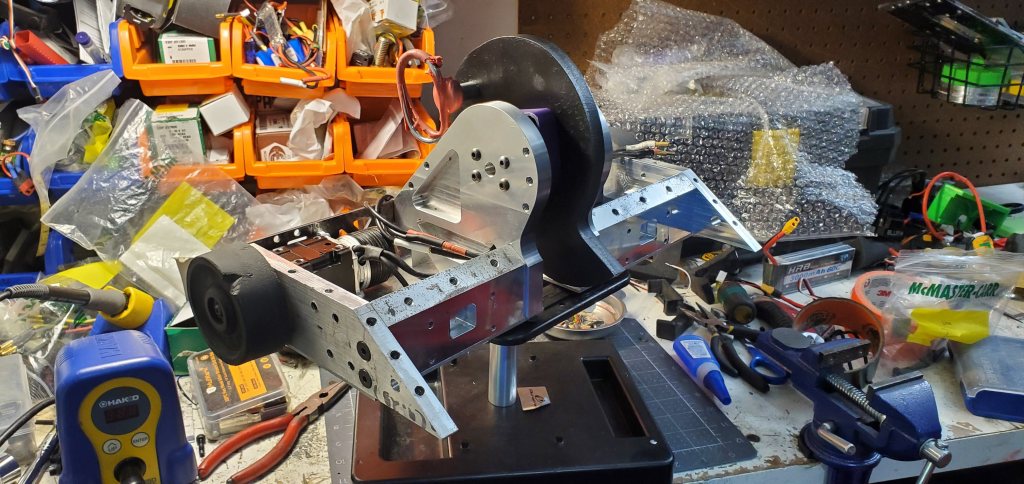

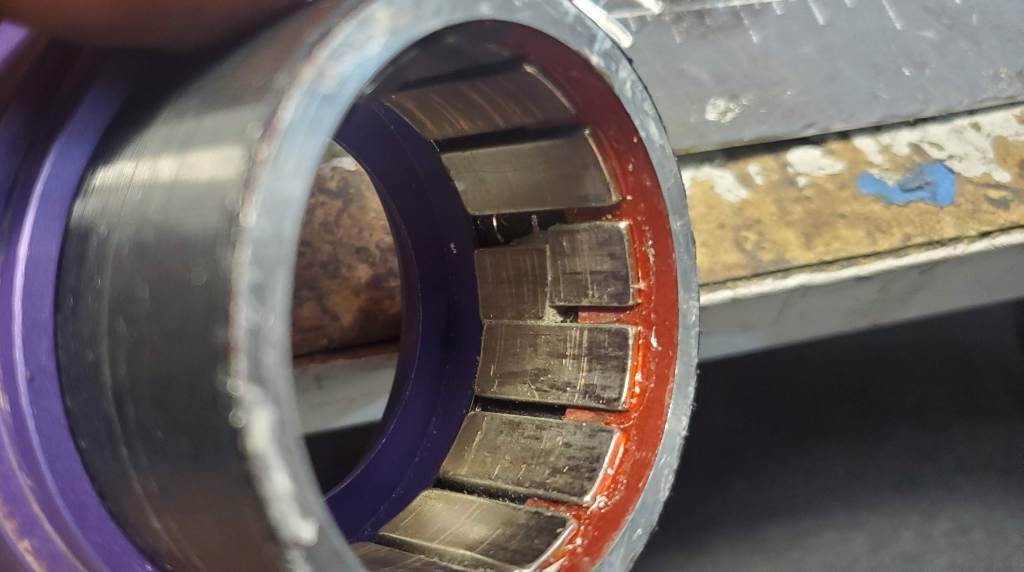

Enter the hubmotor. Based on captain of Honey Cracked and friend Zoe Lambert’s hubmotor design, a modified version of this was cooked up for Phenomenon. This design has three unique components (central shaft, endcaps, and main body) which are mirrored to create a clamping-style in the middle. Thought the motor is now in the center of the action and thereby at higher risk, all of the loading is focused onto the bearings which are very close to the center rails of the machine thereby removing forces from the motor. The motor itself is also surrounded in a thin TPU cushion which allowed both a small amount of slip around the can and a small cushion layer to hopefully limit shock. In addition, because the width of the weapon is only controlled by the connection to the two halves, one could either modify the length of the endcaps or increase the depth of the groove on the hub body to allow different weapon thicknesses. Since most hubmotor designs are aimed to fit one specific weapon this gives an option of future modularity that I’m excited to explore in other machines.

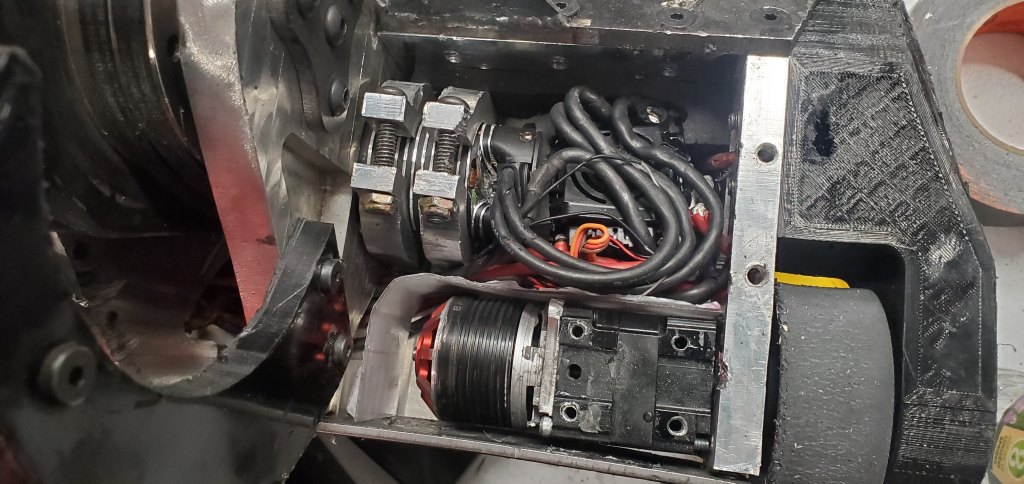

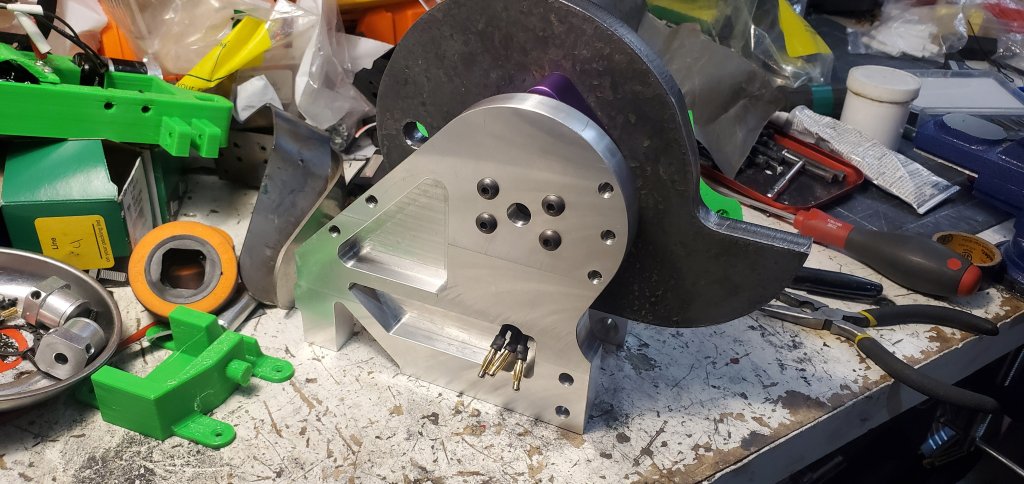

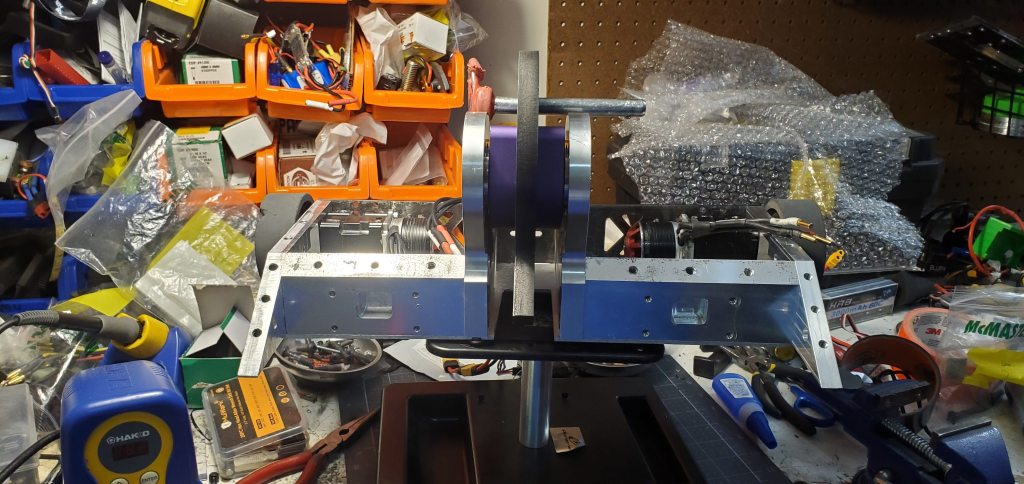

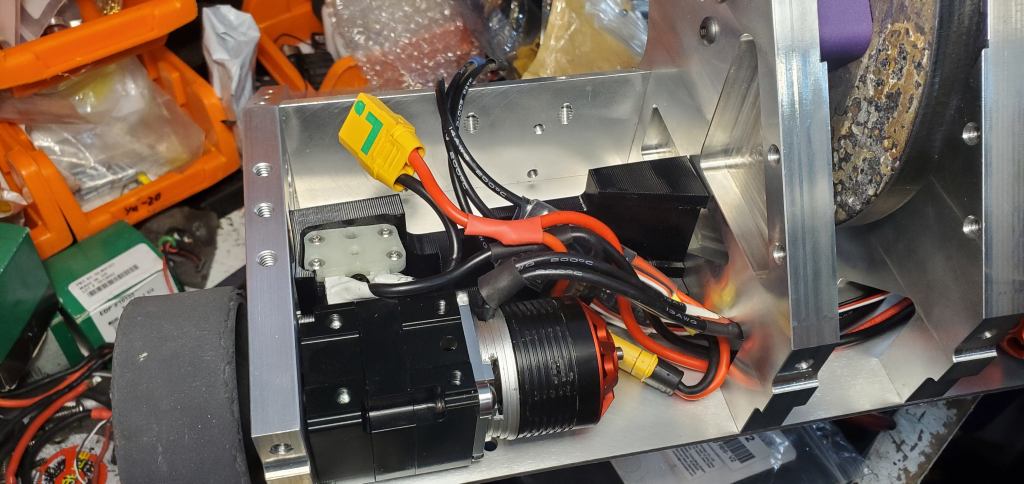

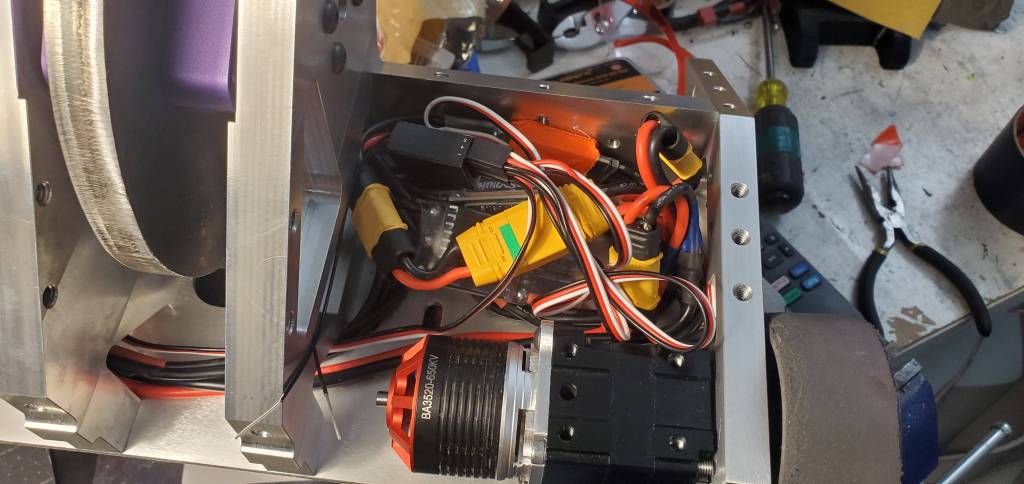

The specific benefits of this were very clear: since the motor (a 4520 470kv that was later modified) was now inside the weapon instead of in the robot there was immediately much space removed and the cutout that the motor used to sit in was removed giving maximum strength to the frame rail. In addition, the outrunner style of this motor meant the drone-style ESCs could be used instead of the Mamba Monster 2 which could further save weight and space. The downsides were also present as well: there was less mass in the weapon system so its not hitting quite as hard as Vorion and the center shaft and endcaps being softer aluminum instead of the end tapped steel shaft of Vorion meant it had less strength in horizontal hits so that will be something to look out for.

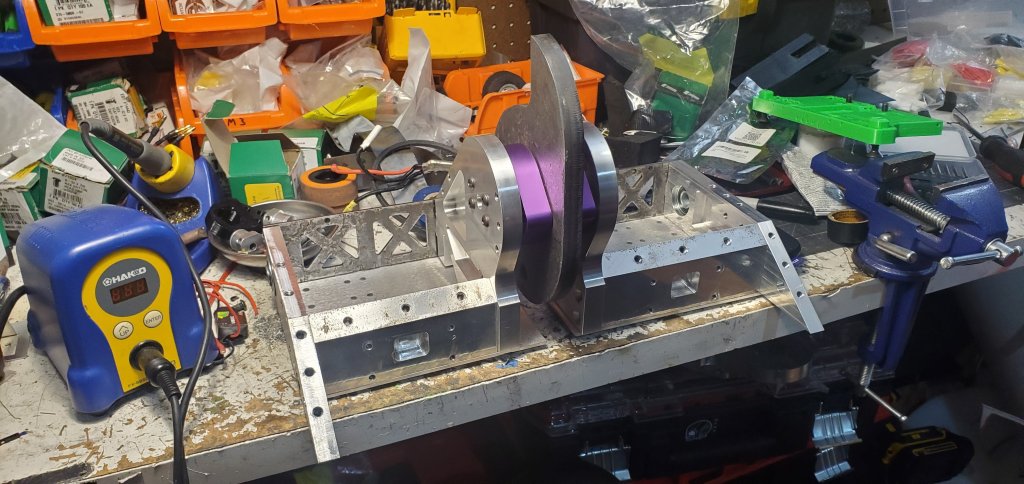

Building

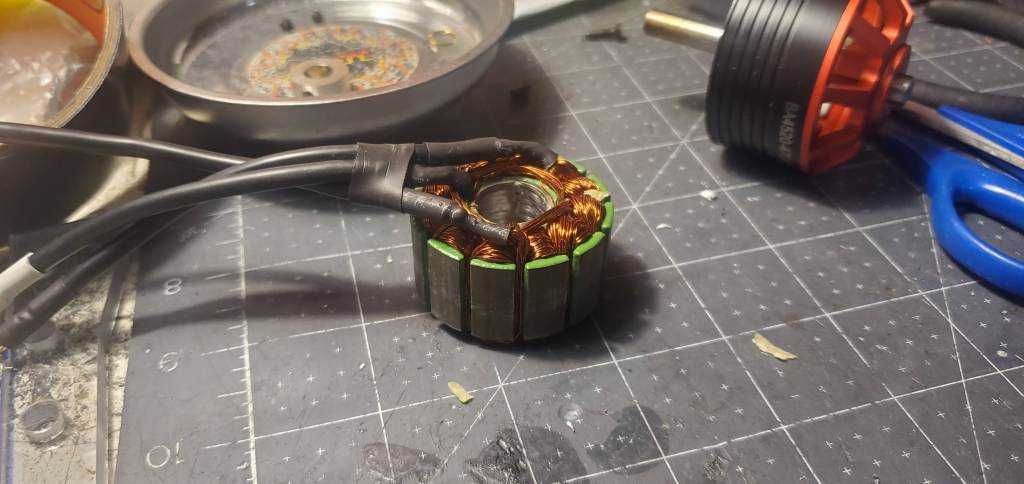

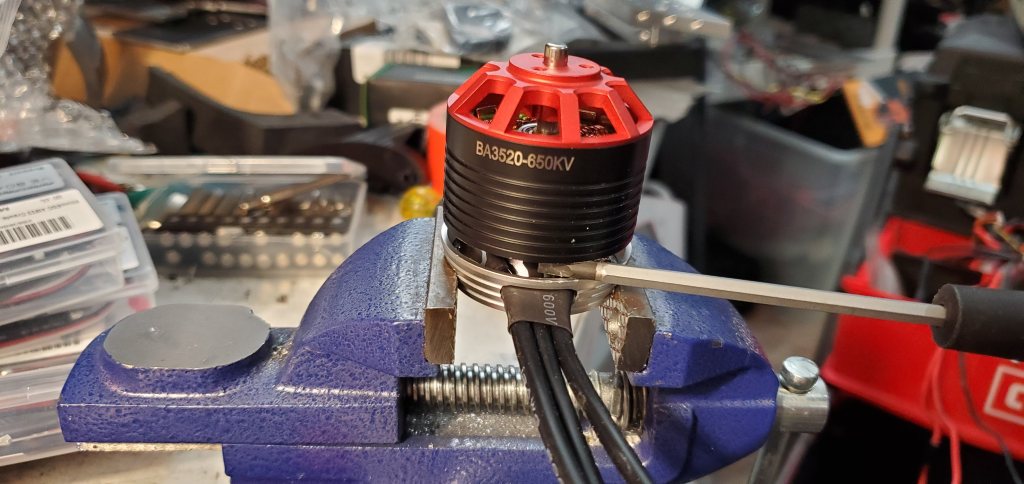

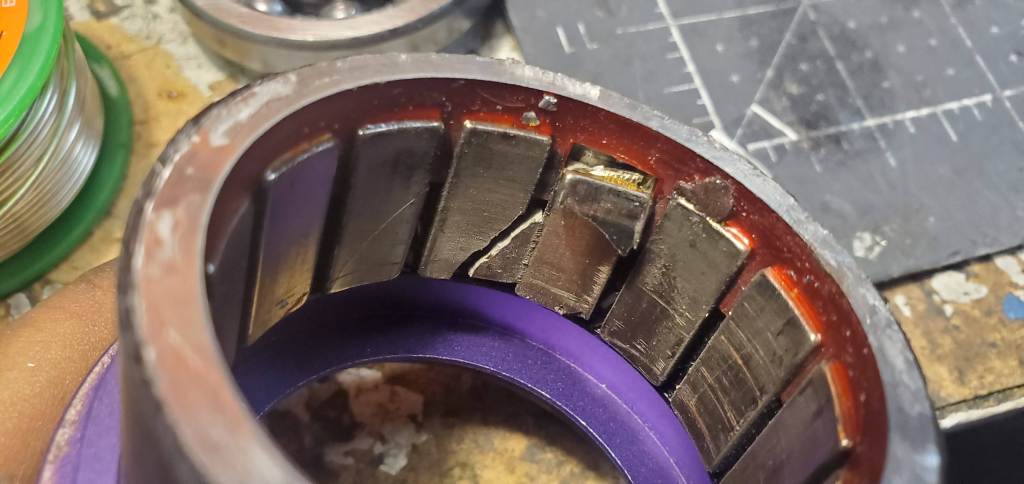

After dissecting the motor, it was time to modify it to match the parts. For the stator it was bored out to remove the mount that it comes with and for the rotor it was put into the lathe to be machined down into a cylinder to fit in the center cavity.

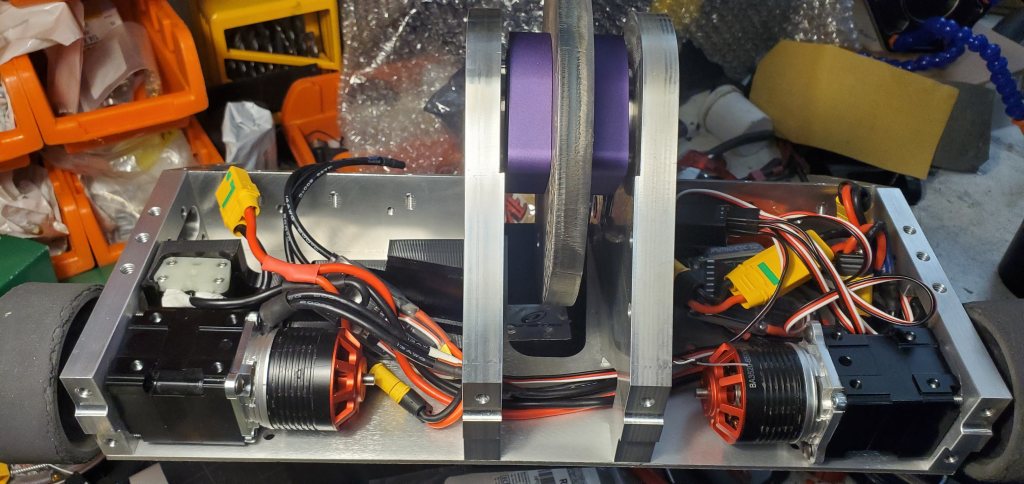

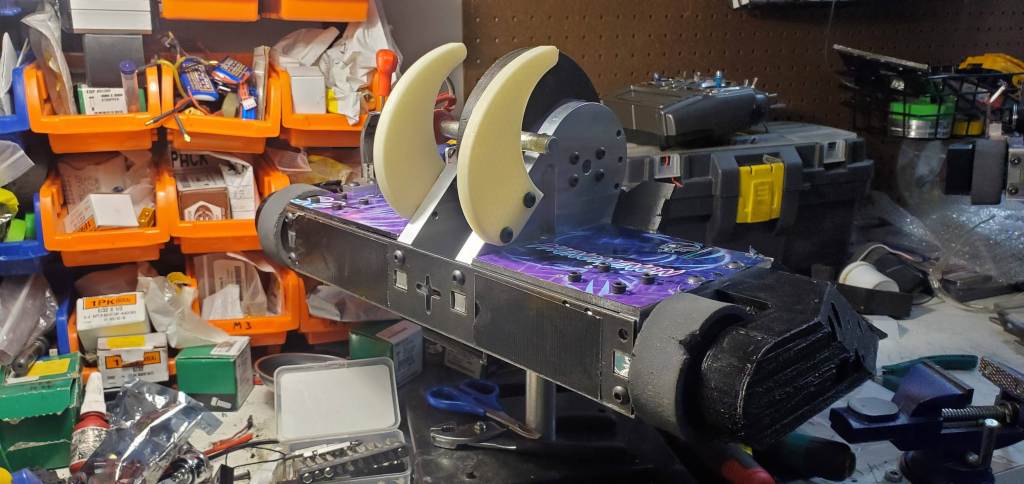

Once the hubmotor itself was installed, the rest of the frame was built around it. You can very easily see how much internal room was gained by compressing the system; three ESCs and receiver could all fit easily. It’s also important to note that the orange ESC shown here is a Rhino 80A AM32 ESC which is the same controller used for drive. While this controller did have its limits, it did allow for effective spin-up comparable to the pulley system and a very simple shopping cart.

After assembling the machine, it was time to go down to test at the Hive. There were a few key concerns going into this:

- Was the motor going to break? Now that the design was going to receive shock from striking targets there was a chance that energy could travel back into the robot and shatter the magnets.

- Was it going to hit hard? Since the weapon hubmotor system is lighter, this also meant the weapon had a risk of not hitting nearly as hard as the original system.

- How much power did it draw? Assuming that the weapon could deliver good hits and not break, would the battery be able to sustain it? Would the motor overheat from so much power? Since there is so much aluminum around it there was lots of thermal mass for the heat to spread through, but in repeated startups there was a risk that the motor could heat up, increase resistance, and kill either itself or the controller preemptively.

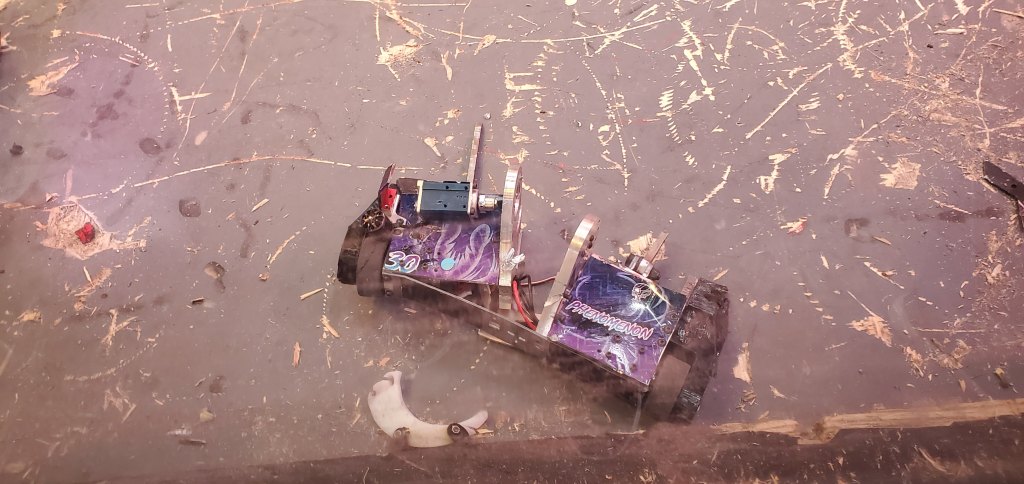

Initial tests looked promising. Big thanks to Micah, builder of Avalanche, for donating the old chassis as a target.

After the test there were a few notable takeaways:

- The weapon did hit fairly well. Though this chassis wasn’t a full 30lb load, it did an excellent job carving into the aluminum which gives room for confidence

- The weapon didn’t break! Even after a full round the weapon spun incredibly smoothly, even easier than the normal pulley setup on Vorion.

- It had more to give. Even in the earlier shots it was not yet at full power so there was hope it would do more even with the heavier load. The AR500 blade being used (chosen for lower cost and simplicity) was already dulling so it will likely be switched with a harder material once the hubmotor had a number of fights completed on it.

Now that the first robot was ready, it was time to construct a second machine in preparation for the June NHRL event.

Second Bot Building

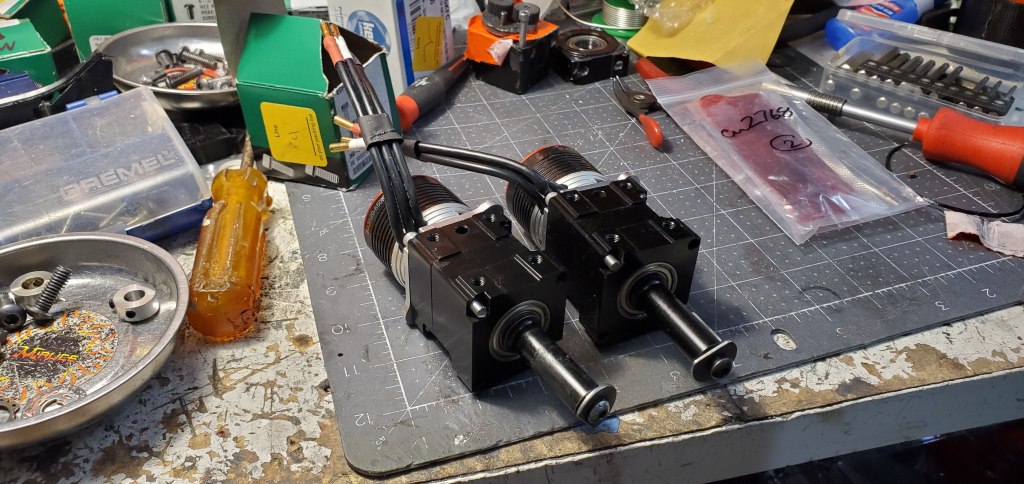

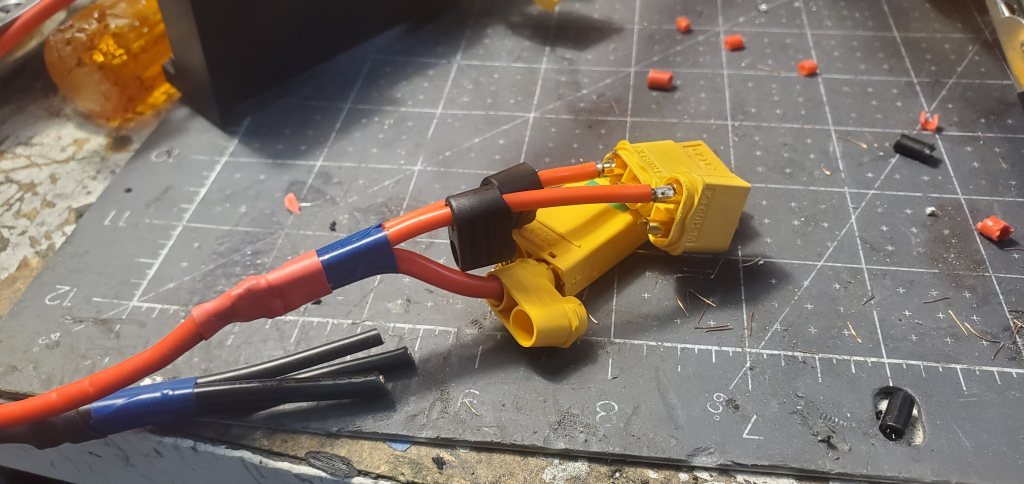

The hubmotor assembly was fairly straightforward since it was the same as the first one and the drive was comparable to the other similar machines. The BA3520-650kv motor used in Vex Versaplanetary gearboxes requires modification to a new shaft with an input to match the Versa. The Versa gearbox output itself is also modified by receiving a deeper groove behind the shaft for retention. The custom mounting plate also receives a layer of shoe goo behind it to assist the bolts just in case of the screws weakening. Keying geometry is also incorporated into the mounting plates to limit the amount of shear forces seen on the motor.

Updated and Improved art was created by Ian L. Springer. With that done, it was onto the event!

NHRL June Qualifier 2024

You can read the event report here. After 4 years Phenomenon finally takes home a dumpster of its own in dominant fashion! You can watch the action here on YouTube. Here are the main takeaways:

- The hubmotor worked! After ramping up the power level over the course of the event the hubmotor passed with flying colors. The blades held up well-enough to not chip much further and the bearings felt smooth. Nothing felt wrong, but these could be examined again before its next event.

- The lifter position was important to drive handling. With the addition of the tip onto the lifting arm its position for driving became more critical. In the fight against Beeforce I had to “tune” the drive by adjusting its forward position to create more downforce on the front and avoid wheelying.

Awhile later I did examine the hubs and there was some shock damage to the rotor. Remarkably I did not feel this issue when moving the weapon so while it is good to know that its light failure mode likely allowed the weapon to keep working even after it broke, I did not want to chance it for a future version. Its also important to note all of this is without the option of adding epoxy around the motors to further support the magnets, further increasing confidence in the future.

At this point, the strategy for the year was to sit and wait until the finals. Since both machines had been successful, there was less imperative to enter it at another competition again especially due to their high costs of damage repair. While it made life at large simple before competition, there was still a feeling of lack as the robot wasn’t actively improving which is critical when watching the opponent iterate across the rest of the year. At the end of this long pause, it was time to get ready for the Finals.

Self-Righting Testing

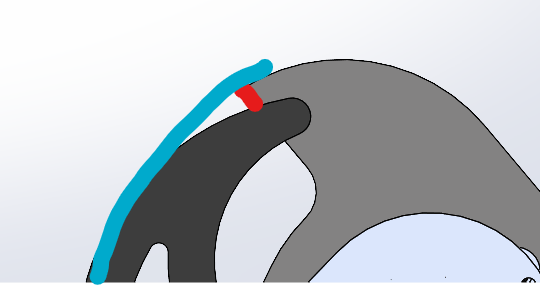

The first learning I wanted to test at the Hive was ear design. Much like how Vorion tested a rounder blade, Phenomenon tested ear shape. The idea of both is very similar: how to best self-right faster without losing control. In this case, the idea was to try shorter hoops closer to the original bunny ears of v1 both to decrease weight and space, but utilize the weapon some to self-right slightly faster. The intention is not to overly rely on the weapon to avoid violently self-righting/taxing the weapon system (which is particularly important in the hubmotor system which has no reduction).To do this, the hoop was designed to be slightly offset from the weapon so at the edge of the hoop’s shape the weapon pulls the robot back forward but then slides down the hoops. As the robot slides down the hoops and rolls back to its wheels, the blade has the chance to accelerate again allowing it to reach top speed by the time it falls back down to its wheels. In summary, I’m “borrowing” some power from the blade to help it self-right faster but still “exchanging” that for time during the passive self-righting portion to get back to speed thereby allowing it to still be at power by the time it returns. You can see everything working in the gif below:

This is the beauty of clones: using them as active testing tools!

Though the procedure did work, I had two other priorities for Finals:

- I needed to consume the existing hoops. Many other hoops still took up storage so I’d rather consume them first if for no other reason than to decrease inventory.

- I wanted to limit stressing on the weapon systems. Using these lower hoops means greater current draw onto the weapon system for each time the weapon slows down. For Vorion this may be fine but for Phenomenon this could be absolutely critical as the upper limits of the hubmotor weren’t fully known yet.

To keep things simple, the hoop shape wasn’t updated going into Finals, but it will likely be tried in 2025.

In addition, I tried using a wattmeter to get an understanding of what the Rhino 80A ESC was pulling on startup and the amount is surprising. 123.8A and nearly 2500W of power is technically beyond the power level of both the motor and controller momentarily. Despite the high peak values, the weapon still worked flawlessly so there were no issues for before final assembly. Time to go compete!

NHRL Grand Finals 2024

You can read about the event here. Here are the key takeaways:

- The hubmotor really does not like being stalled. Moccasin was the perfect machine to test this out as the springy but strong Titanium and Tegris did an excellent job jamming up the system. This created a cascading failure to the hubmotor’s ESC which saw repeated current spikes and eventually burned up. The motor itself in the weapon didn’t die though so it likely has an even higher upper limit. This will be tested more in 2025.

- The lifter motor really needs to move internally. While the lifter motor only got hit damaged once by Synthesis 30 in Vorion’s fight with it, the system as a whole took a good amount of damage by WarHard XXL in Phenomenon’s fight with it. It’s a expensive fix and one which I’d love to avoid again in the future.

With both of these key fixes in mind, its time to move forward to 2025! Tune back in for more event reports and bot reviews!