The original purpose of making Kerfuffle is for the combat robot team I founded at the University of Maryland called Leatherbacks Combat Robotics. This team was a direct result of my desire to build up the presence of combat robotics in Maryland and beyond as graduating students move around. Kerfuffle’s role was to be one of the inaugural competitors for the club’s Showcase of Combat Robotics at Maryland (SCR@M) event as part of Maryland Day. We elected to use Polycarbonate for weapons and PLA as the primary materials since the Polycarbonate could destroy PLA and create a good spectacle.

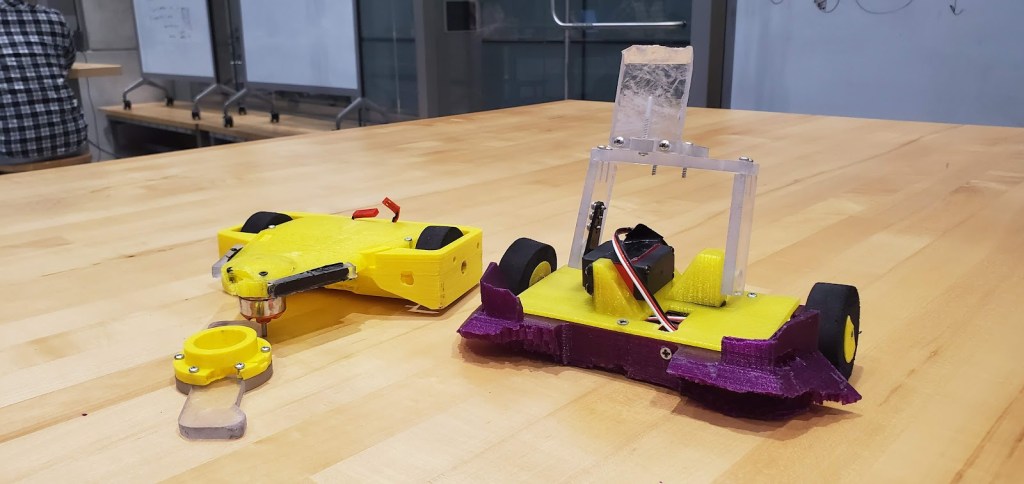

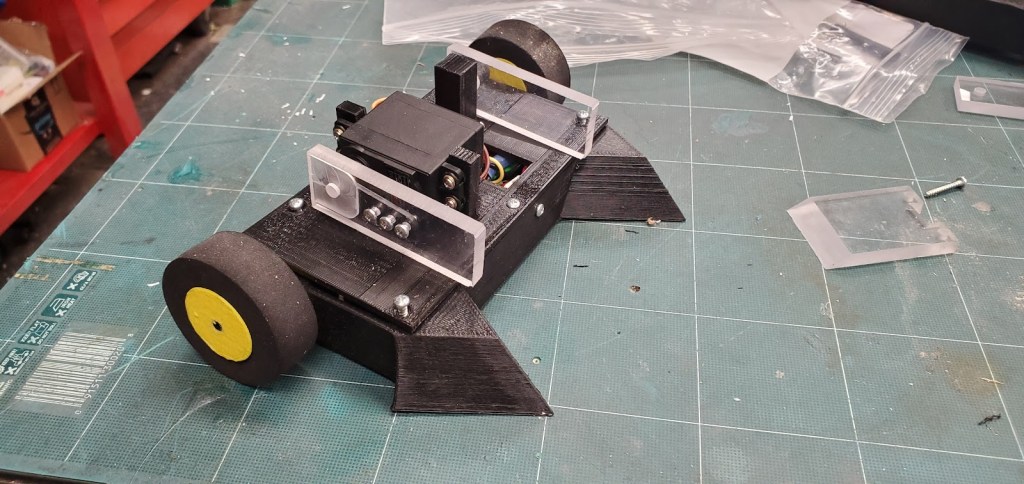

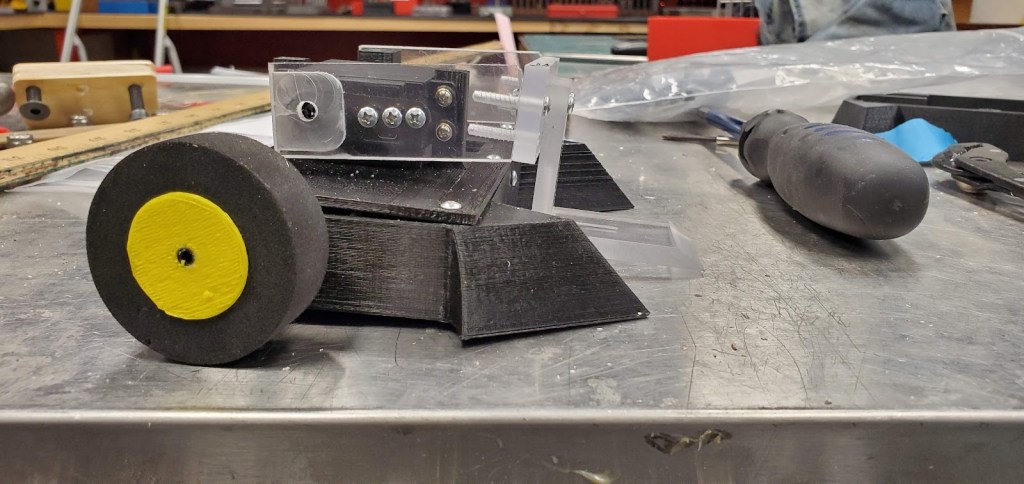

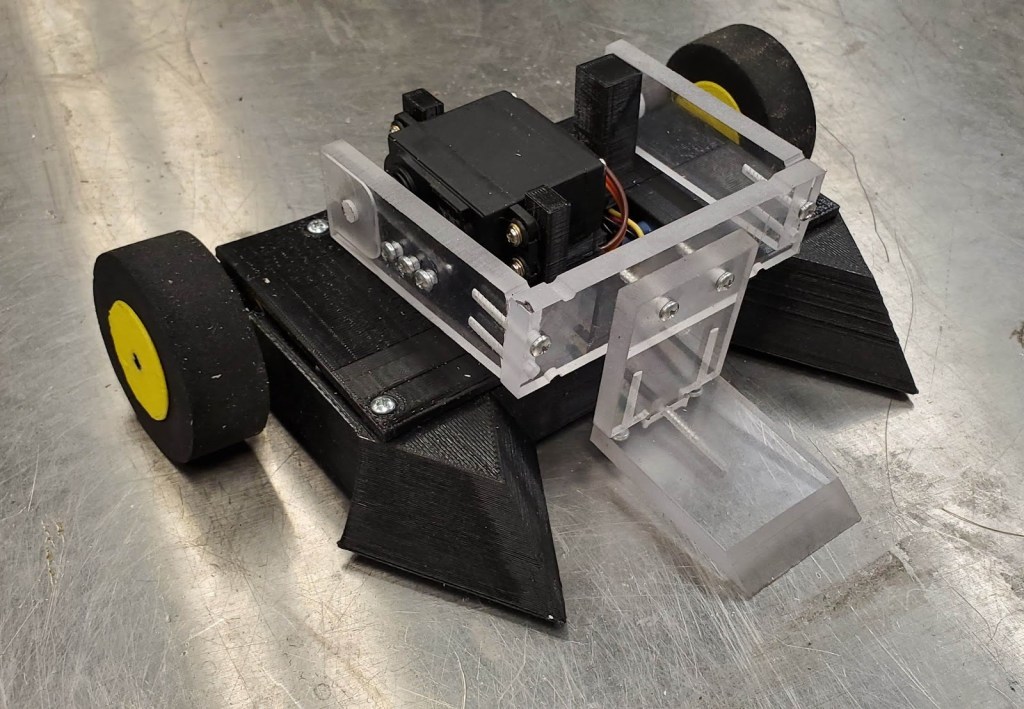

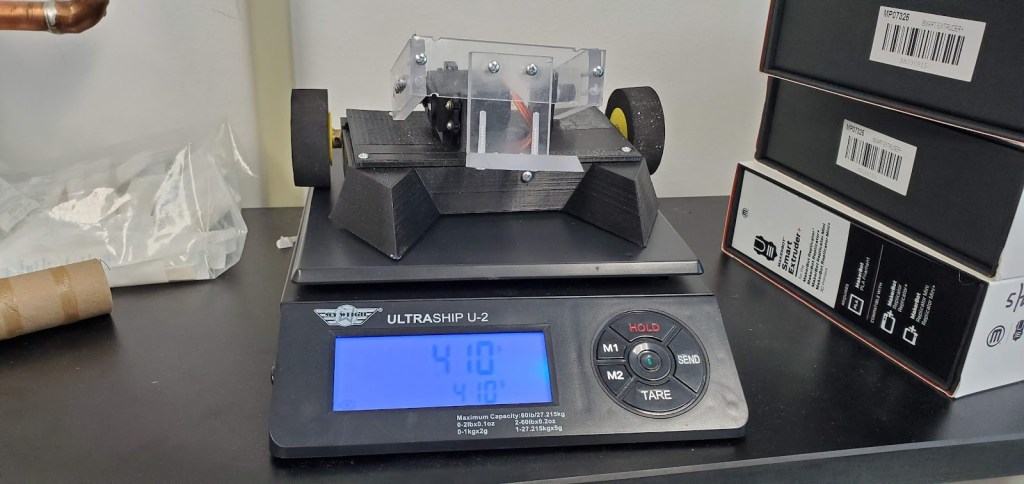

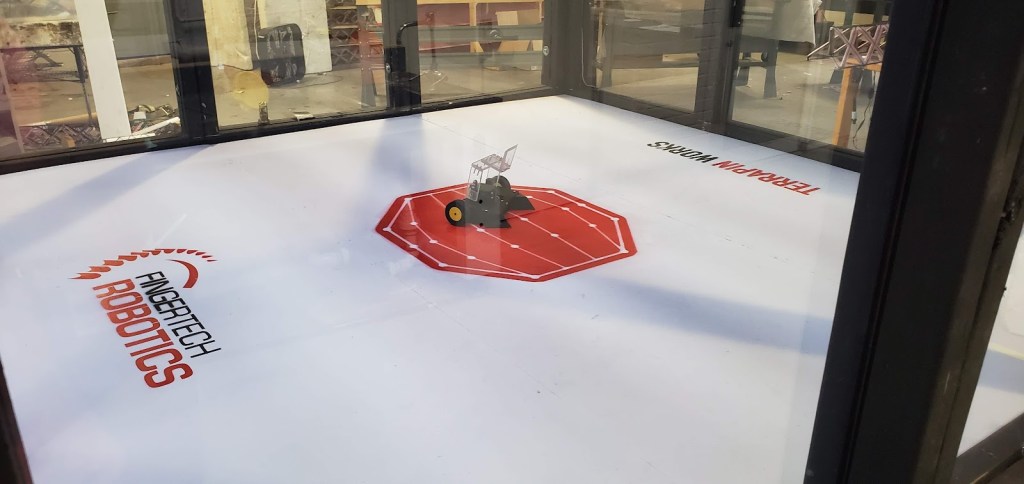

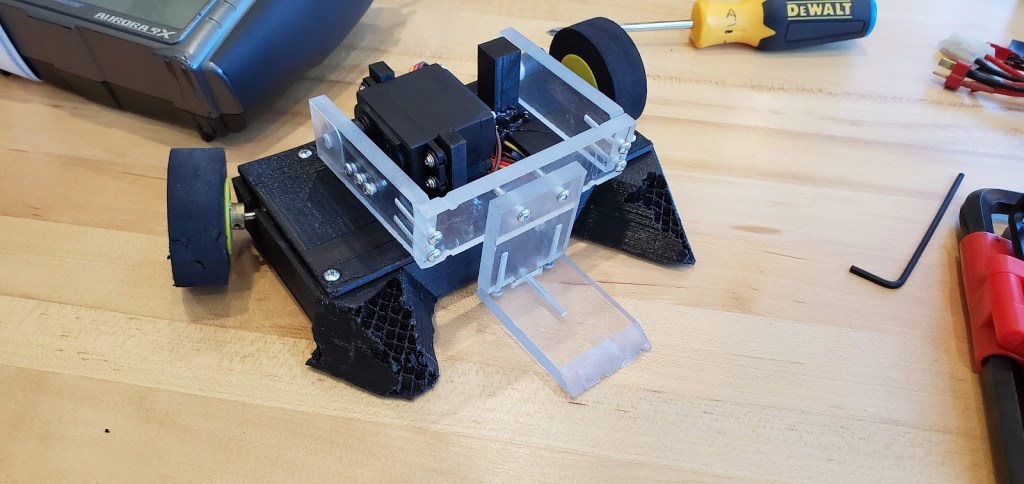

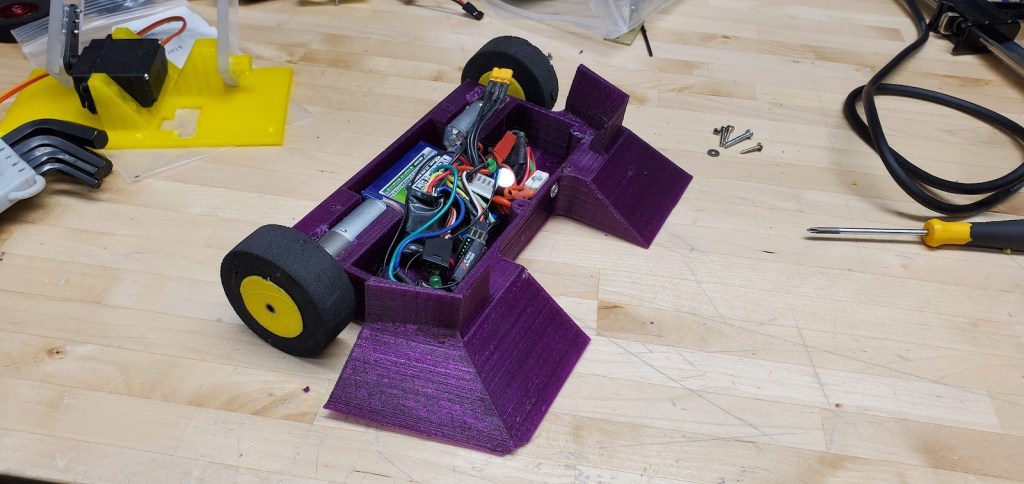

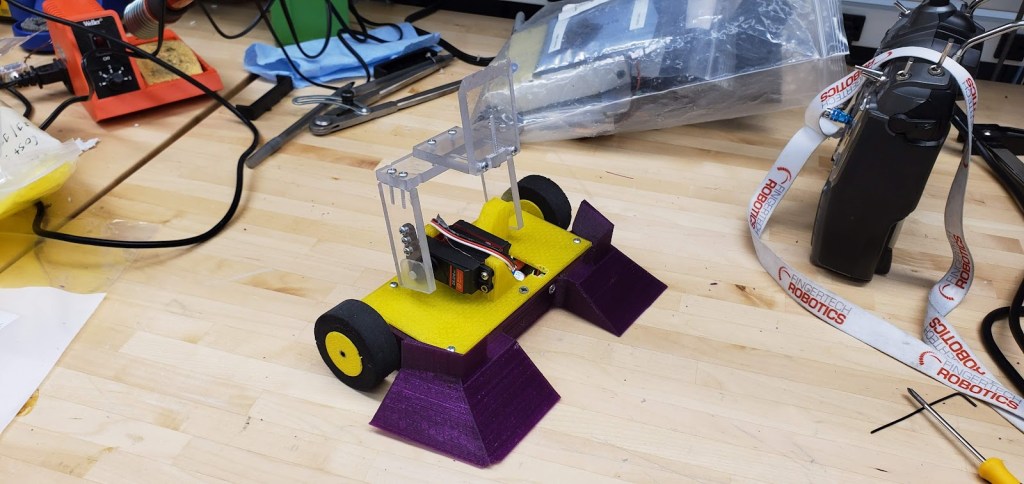

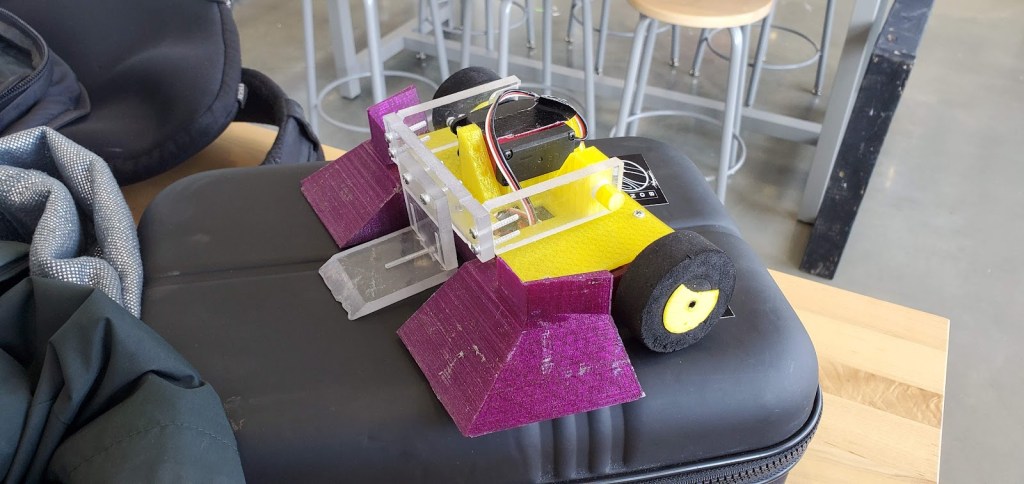

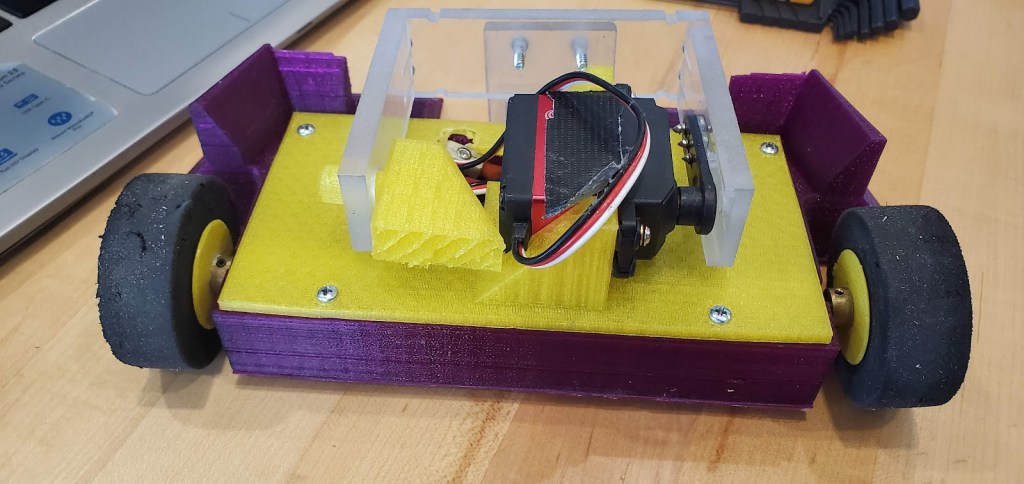

The beauty of 3D-printing machines is that with proper design preparation, the build process for this robot is as simple as hitting go on a 3D-printer! The shape of Kerfuffle is directly derived from the shape of Ferocious so much of its function is very similar. The only machined components are the Polycarbonate rails for the lifter which were waterjet cut then screwed together using plastite screws. There was an issue with the arms keeping the leading edge of the lifter level to the ground. This will be improved on for future versions. Once Kerfuffle was completed, it took some celebratory photos in the center of the Leatherbacks arena.

SCR@M Spring 2019

After the beauty shots, it was time for combat!

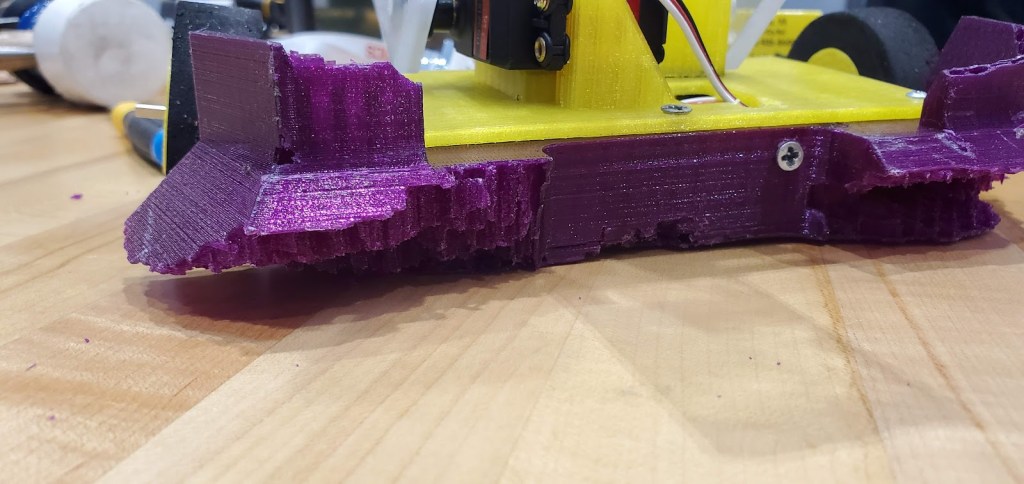

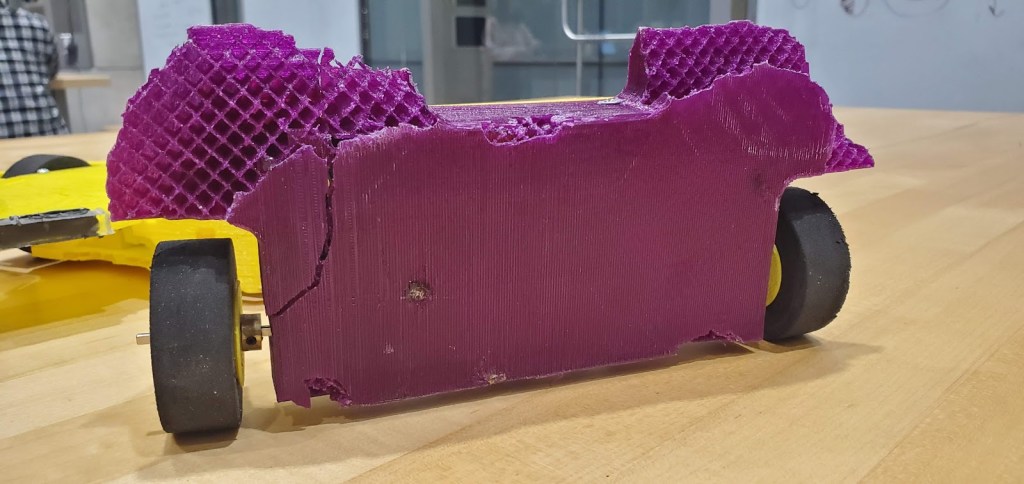

Despite the damage, Kerfuffle proved to be incredibly resistant. It fought against multiple incredible robots including Spin2Win (the horizontal spinner pictured above). Though victorious, the damage was pretty severe. Remarkably, the gearbox did still function and because the chassis was 3D-printed it could be hot-glued back together. As a result, the bot was reassembled with the broken (since there were no spares) and it went on to win the tournament! This victory was a great indicator of what would later come.

SCR@M Fall 2019

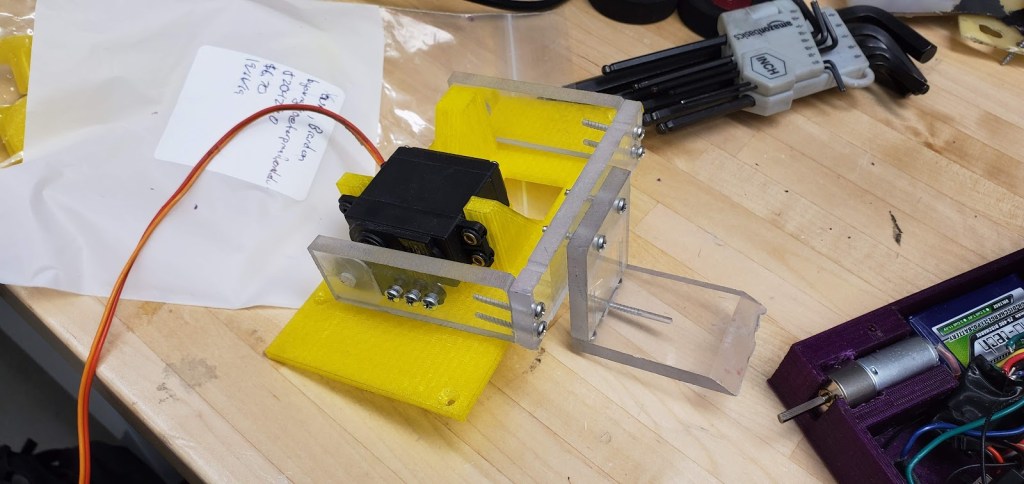

The new Kerfuffle is where I really wanted to connect the name to the colors of the machine. After changing the geometry better to handle the impact from horizontals, new and more fun colors were chosen to print from. If you have ever seen the article from Make: Magazine, this is where that version of Kerfuffle first shows up. You can find the model of this robot listed on GrabCAD.

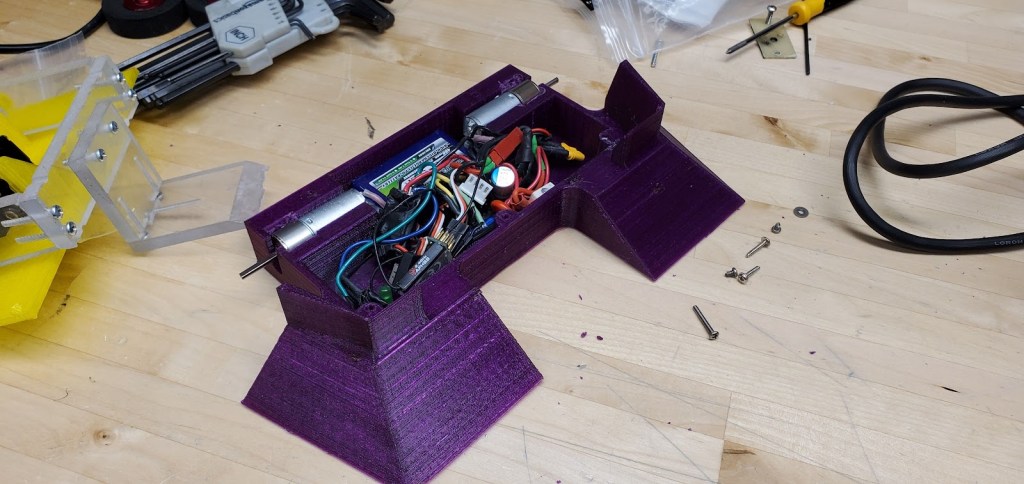

In just a few short steps the robot was assembled and ready to go! All of the components could be left in one piece without any need to de-solder; simply heat the PLA with a heat gun to make it soft, press in motors and electronics then bolt on the top plate! Now on to the competition!

Most of its matches were very tame with only the arm support coming off which isn’t great, but it doesn’t affect function too much. All in all the geometry proved very effective in deflecting the weapons allowing the weaker PLA to handle shots from the Polycarbonate.

In a survival battle against Spin2Win after the main competition, the limits of the PLA body were tested and it became clear geometry could only last for so long. You can even see into its chassis to see the battery! A fitting sendoff to the chassis after a long day of combat.