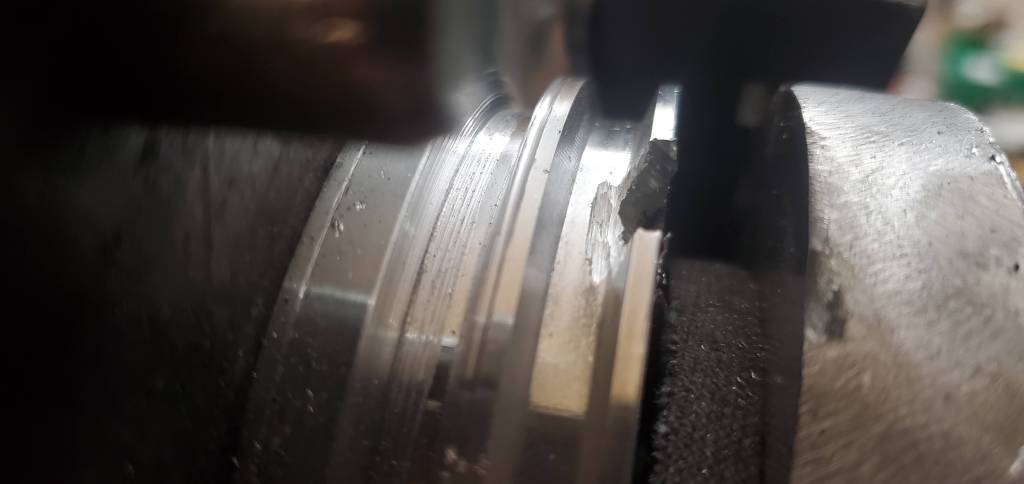

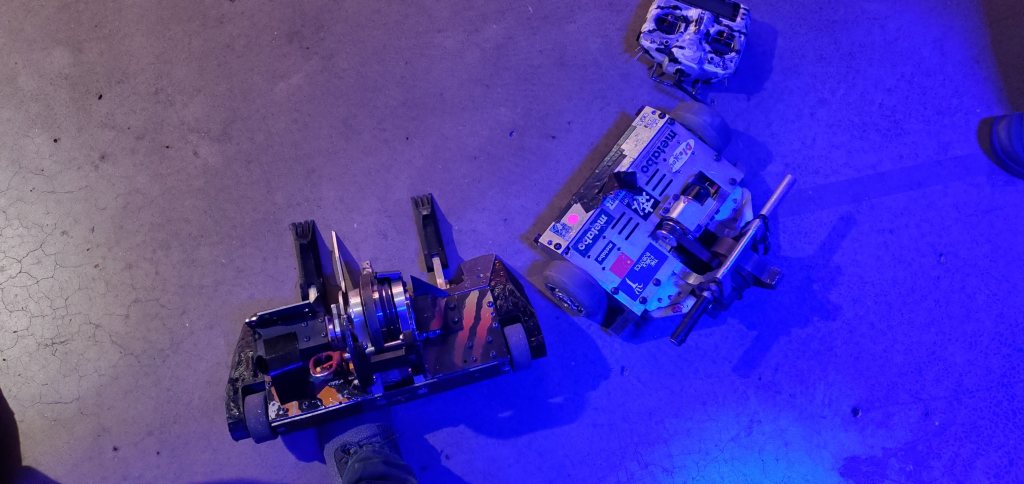

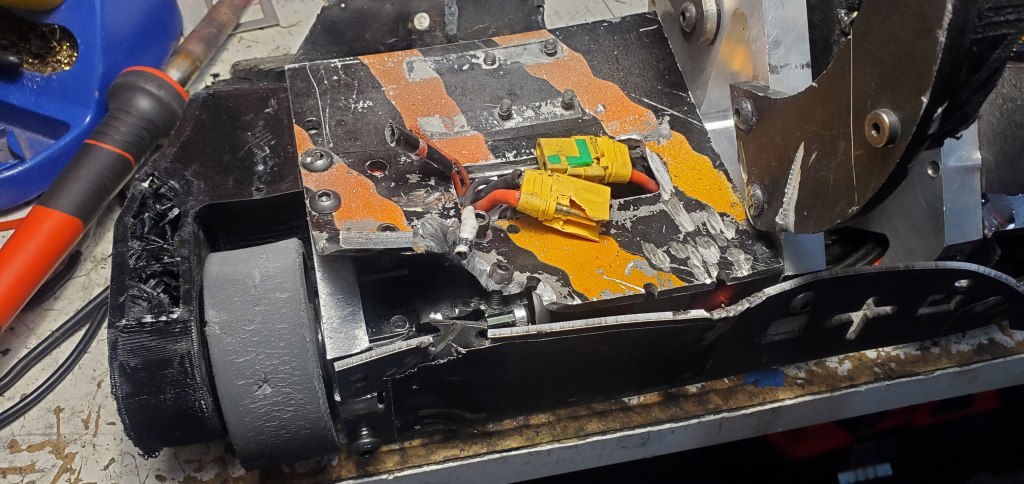

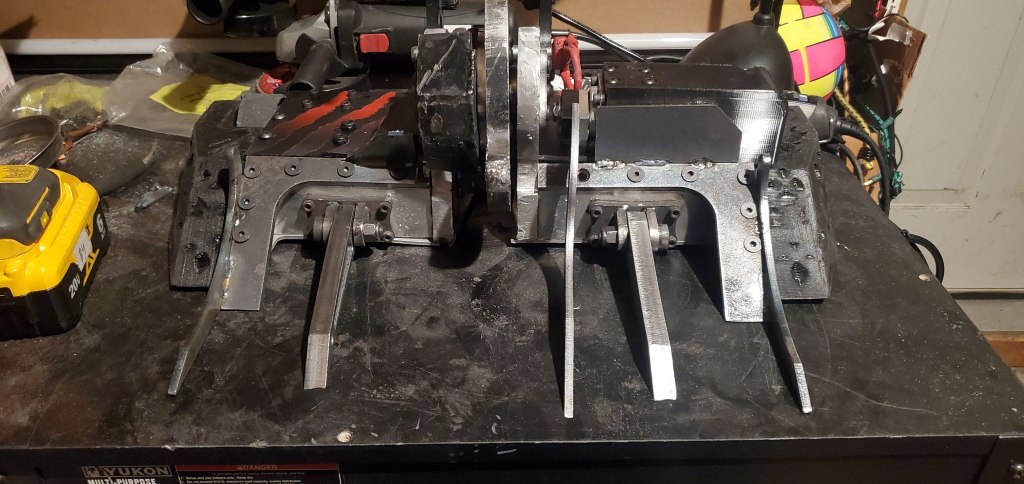

Vorion began the year in a pretty good state. After winning the NHRL All-Stars title, Vorion was generally still together with at least one machine still in good shape. However, the other machine which fought against Knock Off White did have some damage to its weapon components. After some very precise shots, the ESC, motor, and weapon pulley hub were all struck and required replacing. The hub was reground with a rotary tool to remove the jagged material and smooth it out

Hardfacing

The next big activity was to see if the blade could be restored. Due to the high concentration of stress on the tooth on impacts it tends to wear down whether it is made from AR500 or AR600 or any other fancy material. However, in an effort to avoid having to cut new blades after every event, I have sought to restore those blades using a process called hardfacing. To do this, I used a TIG rod called WeldMold 958 which does not require further heat treatment but works after cooling. After preheating the blade to ~200F I welded on the material then ground it down to a sharp edge but rounded off the edges some to avoid chipping and maybe remove a little less air resistance. Preliminary tests by scratching it against AR400 scrap and an AR500 blade showed it being harder enough to leave a scratch indicating a higher hardness. The exact amount would need more refined tooling but this was sufficient for now.

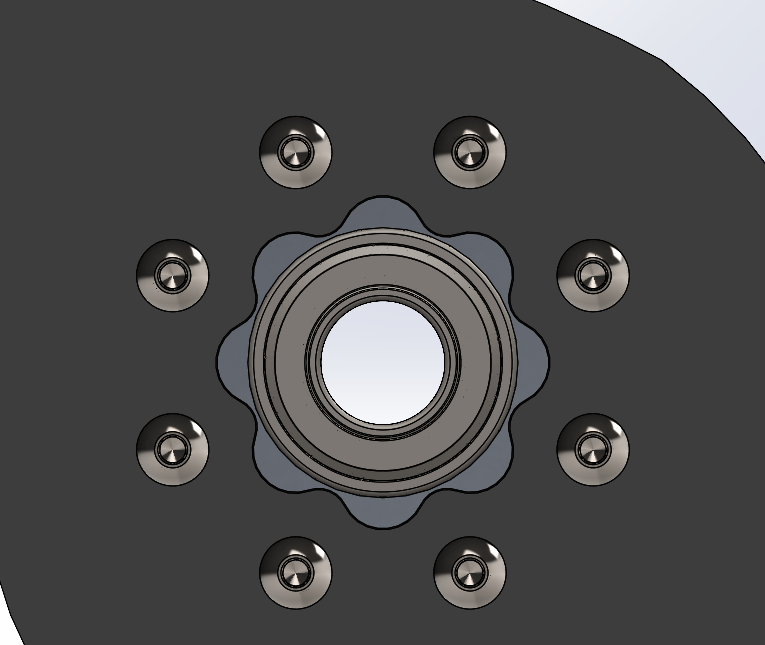

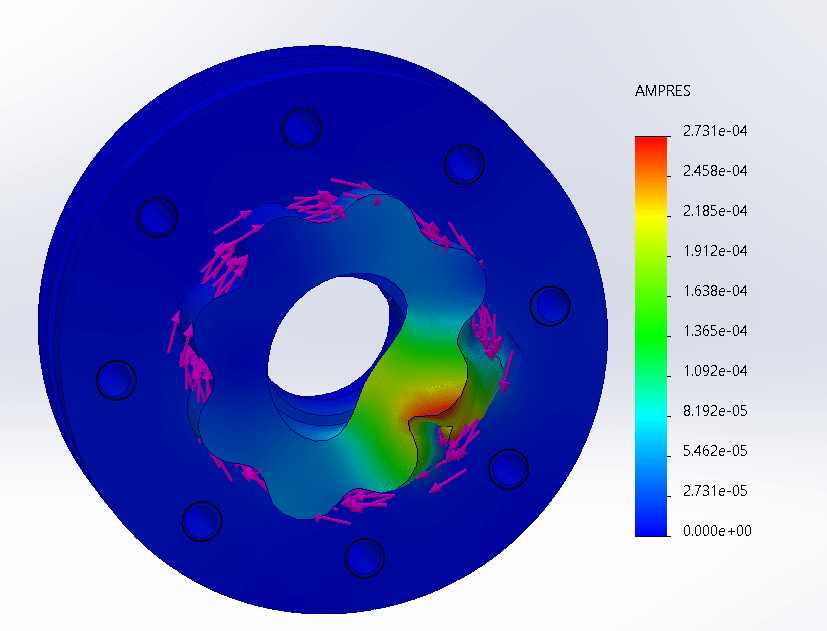

Ball Bearings

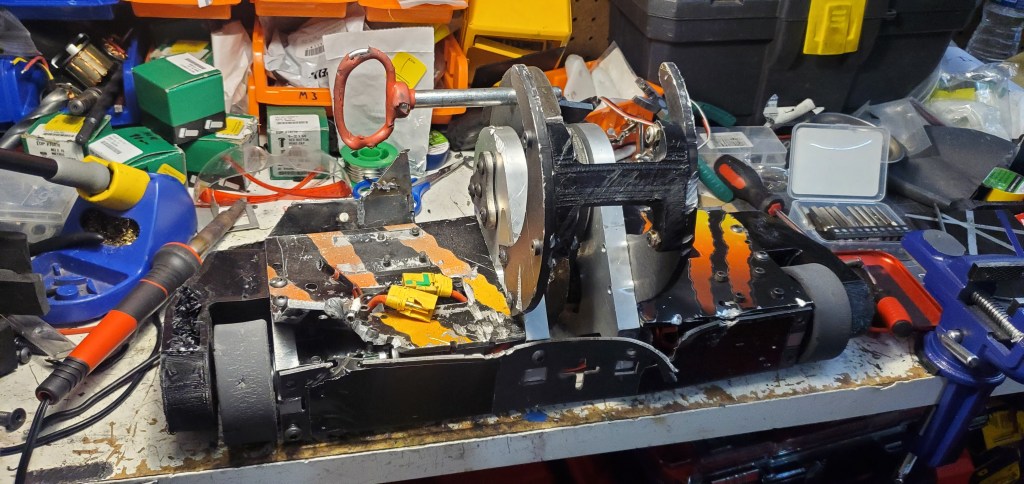

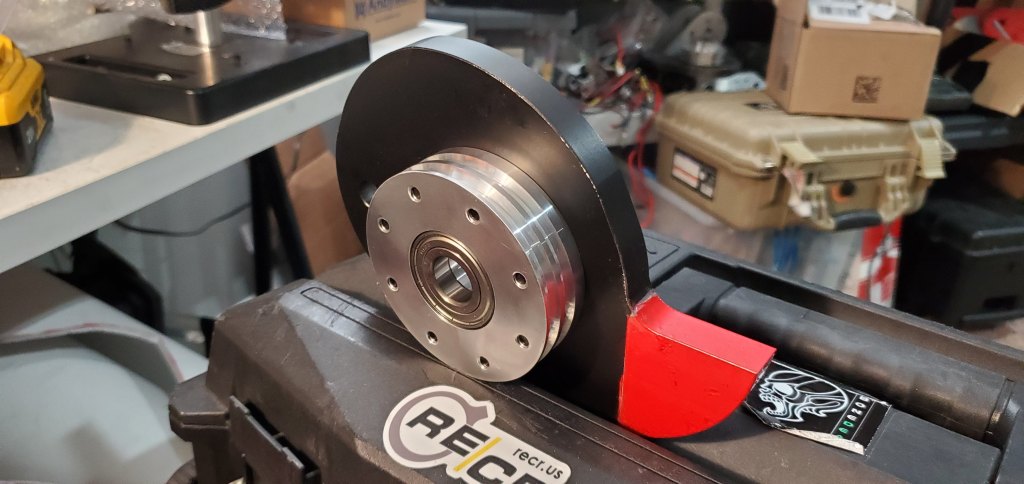

One of the other changes I wanted to make to Vorion was changing the pulley from needle roller bearings to ball bearings. While the smaller needle-roller bearings were good, as the power level of the weapon grew the bearings would end up exploding and/or denting the steel shaft. During testing, I noticed the weapon rolling unevenly over the shaft as the needles created little craters in the shaft. As I was taking the machine apart for inspection, the needles all fell out leaving only the outer casing; they were only maintained by the weapon assembly! While this was good as it means it likely failed in combat but failed in a way that allowed it to still fight on it’s not great if I decided to take apart the bot then and there and all the needles fell out and/or have to worry about replacing them often. As a result, it was time to see if ball bearings were a possible replacement.

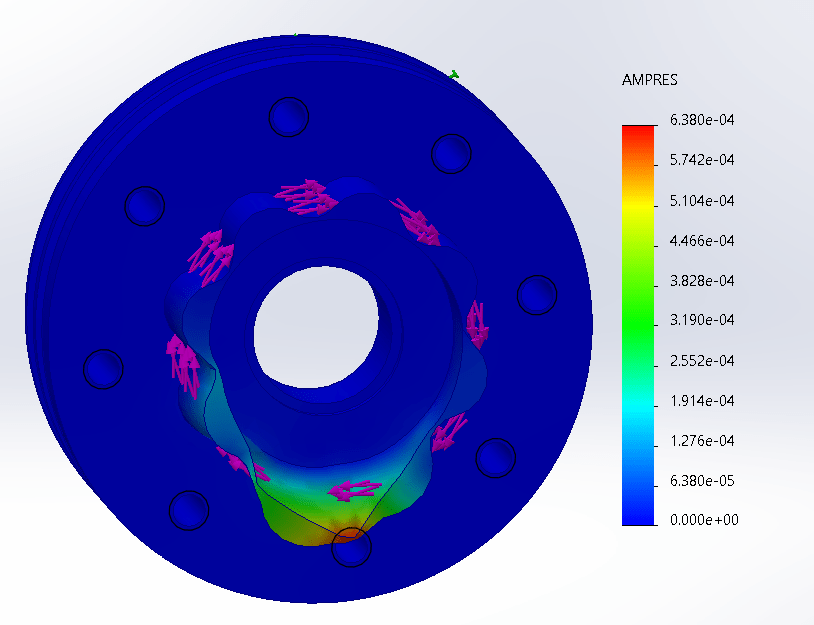

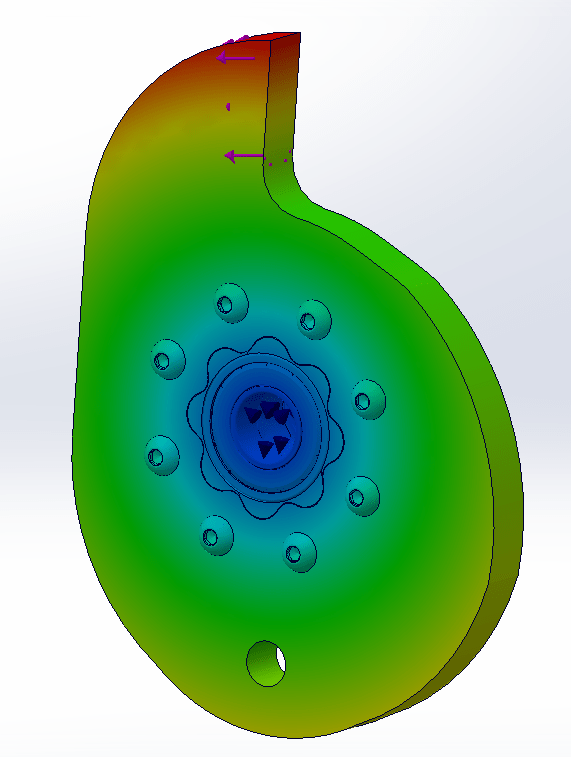

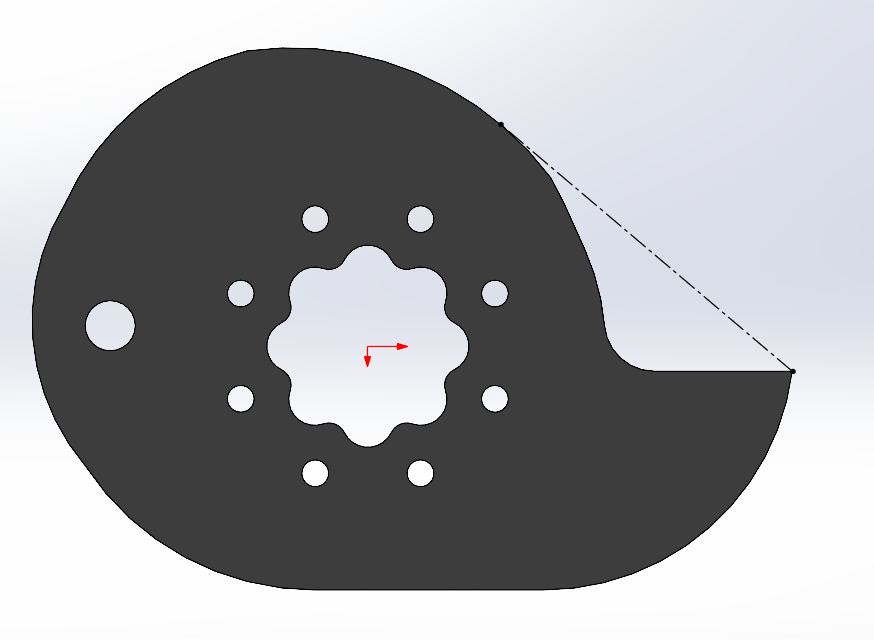

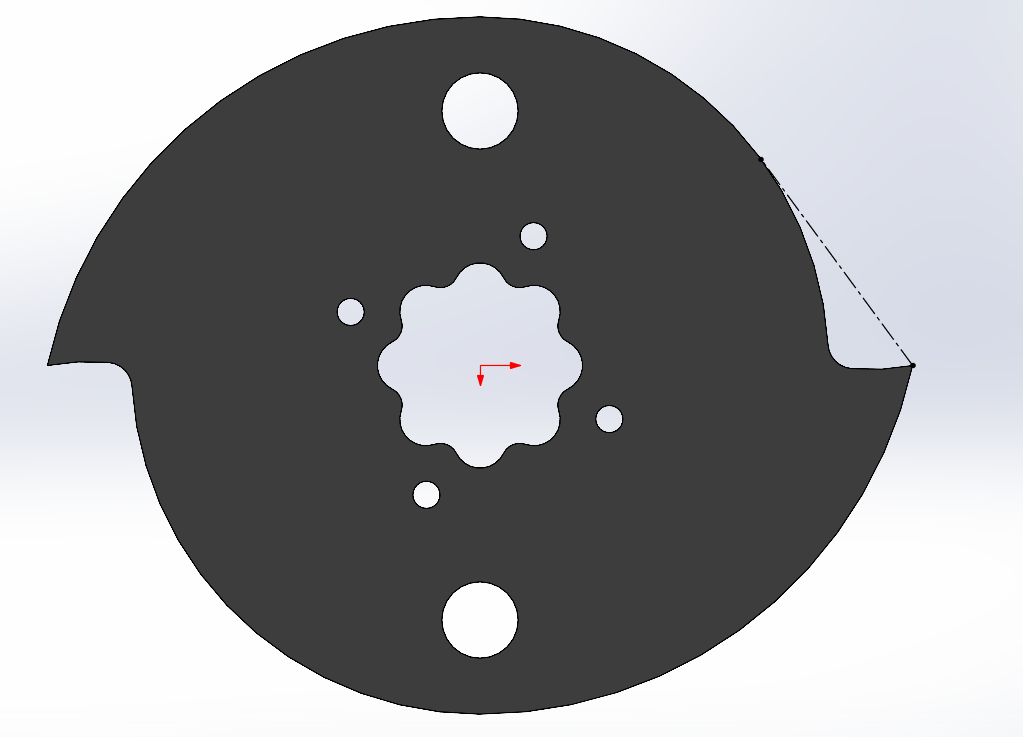

The initial modeling of ball bearings in the hub was concerning as it is so close to the edge of the spline. In order to see how big of an impact that has to overall strength, I ran some FEA studies to observe the difference. It’s no surprise that there is more weakness in the more hollow structure but I was surprised how relatively low difference there was between the two. Once put into an assembly with the blade and bearing I was glad to see the load spread out more and less stress go to the hub.

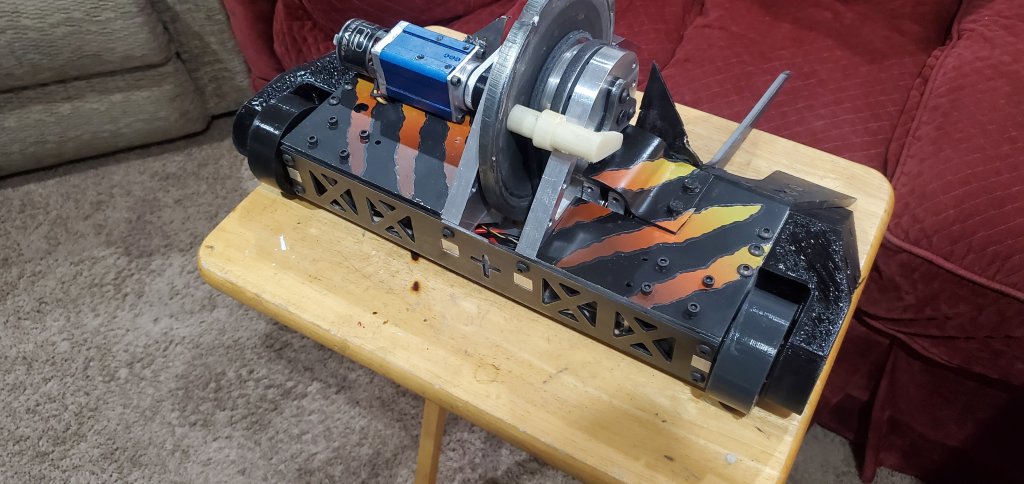

Once the big updates were finished, it was time to switch to the aesthetics. Traditionally Vorion’s claw marks were painted on but due to both time spent fixing the graphics after combat and the variance between each new paint job I elected to try stickers. After a bit of work they went on and looked very consistent so I’ll definitely be using this method again in the future.

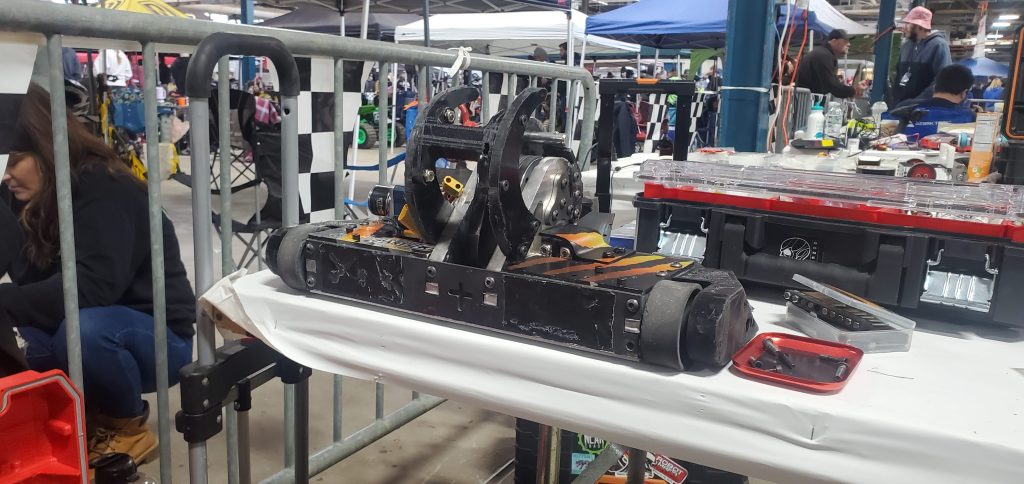

With the updates all applied, it was time to look forward to Vorion’s first competition of the year at Motorama!

NERC Robot Conflict Motorama 2024

You can read the full event report here. Vorion’s test here was pretty good. In general the machine handled itself well against more conventional components but the likes of Pepe Silvia posed a significant challenge and the forks found their limits. Here are some key takeaways:

- The exposed lifter gearbox is a liability. Though the machine is largely able to avoid this difficulty in most situations, it is very much a weak point in unfavorable exchanges (i.e. when they go over the front guards or around the weapon). Ultimately moving the gearbox internally required too much reworking of the robot so this would have to be delayed and a shorter stop-gap measure implemented later.

- The long forks are a liability. Though they are really good straight-on, if they are caught from the side they become a catch point that can either see them or the mounts receive damage. This was the flaw back in November 2023 when Emulsifier fought Vorion and was able to bend the forks by hitting the side of them.

- The hardfacing on the weapon wasn’t too bad. While it would still require more hardfacing over time, it was sufficient for keeping the disc useful throughout a tournament in some very solid shots.

Post-Event Repair

After Pepe damaged the blocker, it was grinded off then repaired.

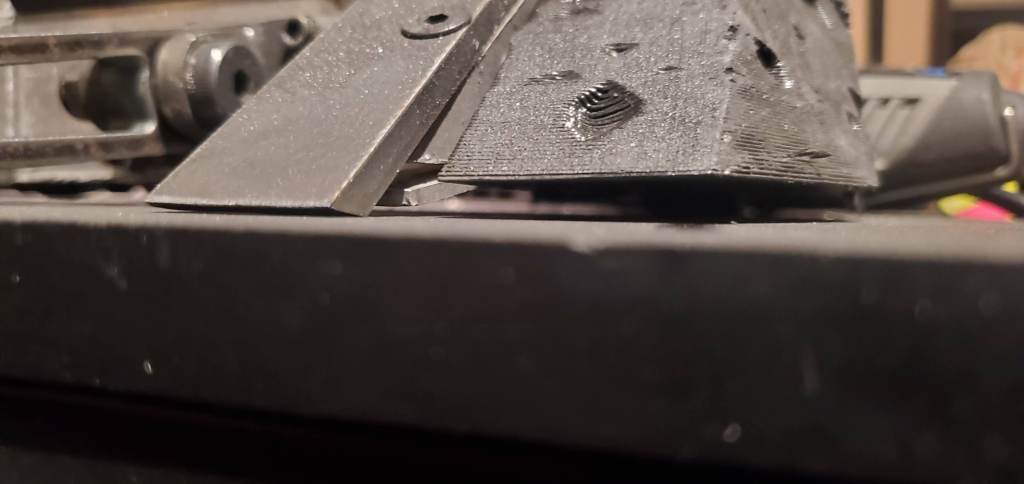

To address my concerns on side-swiping forks I began cooking up this TPU-steel solution. The tip of the fork is printed from TPU with a high wall count and infill (though I don’t directly recall the settings at this point in time) with a few key points informing the shape. First, the tip of the fork has multiple little fingers which give it a slightly better chance of getting under the opponent (instead of having to worry about one edge they could in theory lose to or tie any of the other three). Second, the top of the fork points upward enough that even if the opponent has a higher ground clearance and runs over the tips, they would run up the body of the fork and still be lifted up some by the time it approaches the spinner. Third, the tip is long enough so it can outreach the common fork lengths around; if I can get under them before they get under me then it sets up a favorable interaction. The base of the fork is AR500 steel which is best for both limiting the range of the fork (the end stops being made from steel are less likely to deform) and as a backup in case the TPU tip is torn off. It is short enough where it only sticks out a little beyond the side bracers so if someone does strike the side it should not transfer any force to the main part of the robot. This idea of minimizing transferred damage is shown by the built in gap behind the TPU portion.

A trip to the Hive proved the robot was functioning well so it was time to get ready for the March NHRL event!

NHRL March 2024

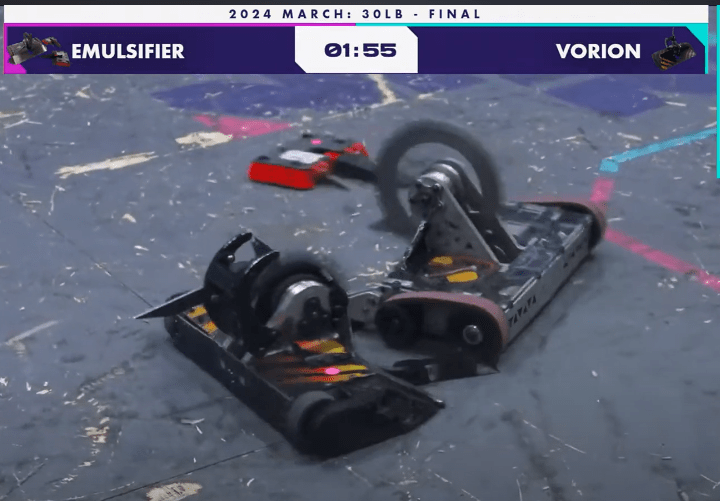

You can read the event report here. In short, Vorion’s fight against Emulsifier was among the most anticipated rematches of the year for my machines so I was very pleased to fight against him. It was a every careful and skillful situation which I described more in the event report but it highlighted the incredibly small differences that drive entire fights.

The difficult part about this fight was that there weren’t many “new” takeaways for the event. I had already known for sometime that the lifter protection was the Achilles heel of the robot but it was one that I couldn’t fully answer without considerably more time and investment. Next to that, the forks actually did work for the goals I wanted to get (they avoided transferring damage and did at least tie Emulsifier’s forks) but clearly more was to be considered. The goal remains the same, but clearly more needed to be done to get that last extra percentage.

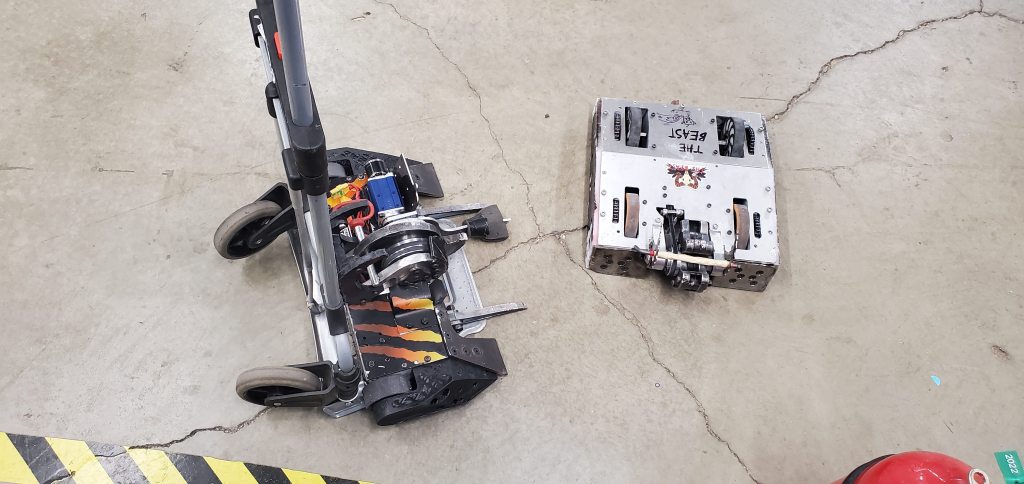

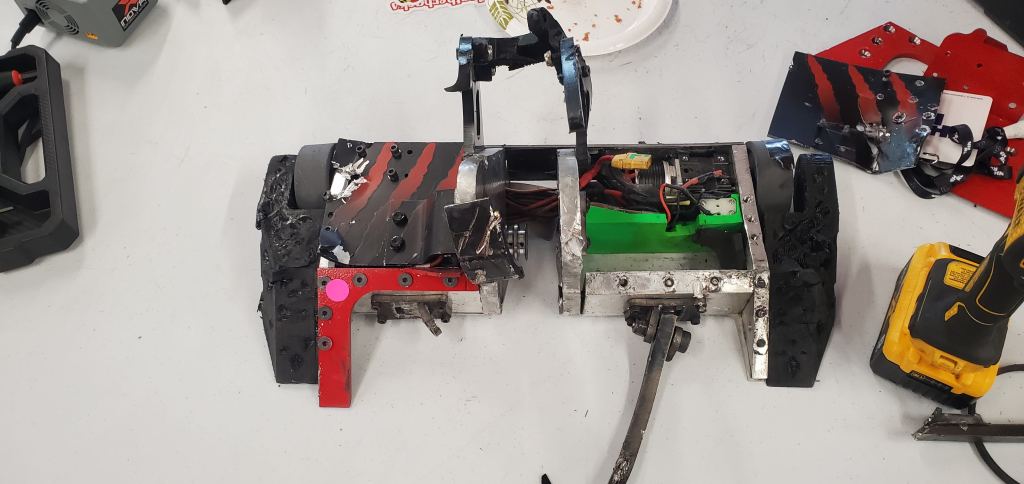

Repairs

Despite the beating, Vorion was “undamaged” in the sense that all core functions and components were still functional at the end. I’d like to say that means Emulsifier doesn’t hit hard (lol) but really its more of a testament to the nature of how he struck the machine. When Vorion was first struck nose-to-nose it gouged through the aluminum, but because the energy was so high it basically machined away the material before much energy could go to the rest of the robot. This is an example of how 30lb robots tend to “break not bounce” the same way 3lb robots do; the inertia of throwing the machine is higher than the strength of the material staying together so most times 30lb robots will never get roofed but will definitely break. It is only in cases where there is either lots of material or the material is super strong (such as a weapon assembly) where the material strength is higher so the robot gets thrown instead.

The other part of the equation is the damage to the lifting arm assembly. Since Emulsifier struck into the chassis onto the lifter gearbox, the gearbox took a bunch of force and spread it along the top plate over a wider area than the point of the blade. The gearbox itself is also about 2 inches of steel and aluminum of varying shapes and thicknesses so the energy of crushing all of those pieces versus throwing the robot meant that throwing Vorion was far easier. This positioning of the gearbox is by design though as Phenomenon’s first run-in with MegatRon taught me you always wanted to protect the battery. Even in the fight against Pepe at Motorama I would much rather see Pepe damage the lifting motor and gearbox instead of potentially grabbing the plugs and/or battery. It’s a very costly gamble though as each gearbox combination is >$150 so its a very expensive ablative armor as well as a chance to knock-out self-righting fairly early on (which is what happened in that fight). Though a inevitable switch to internally-driven lifter is on the way, I am slightly concerned about such a scenario where the top is struck again and the battery is punctured but I suppose that will simply come down to building a better bot as a whole to mitigate that situation.

Teams Prep

After fast forwarding some months, Vorion was selected to compete at NHRL Teams event. Since Teams is considered a special event outside of the normal season there was no record penalty for wins or losses so it was a perfect way to test out some ideas. With the learnings from the Emulsifier fight in mind, it was time to upgrade the machine and see how it worked.

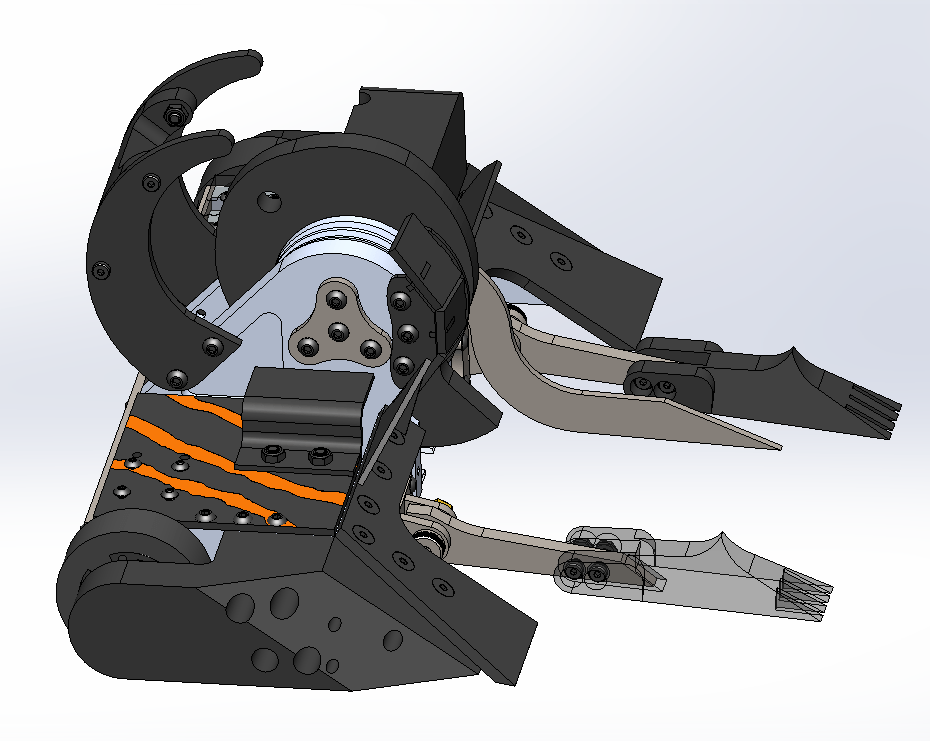

One very exciting idea was to create wider fork mounts utilizing some of the wheel guard mounts and the service hole in the outer frame rails. In the fight Emulsifier’s greater width meant he could touch the bracers on Vorion first and tilt it up (the bracers are not optimized to be perfectly ground-scraping but rounded off to aid drive handling) effectively negating the center forks’ ability to control the fight. By adding outer forks, the opportunity for tilting Vorion gets much harder as the bracers come down to a narrower point and is instead flanked by more forks. The bracer still maintains pressure on the ground and keeps the robot moving well but the fork is what actually plays ground game and hopefully either ties or beats oncoming machines. In addition, its wide stance means it can easily corral other machines into the blade and/or further protect the wheels.

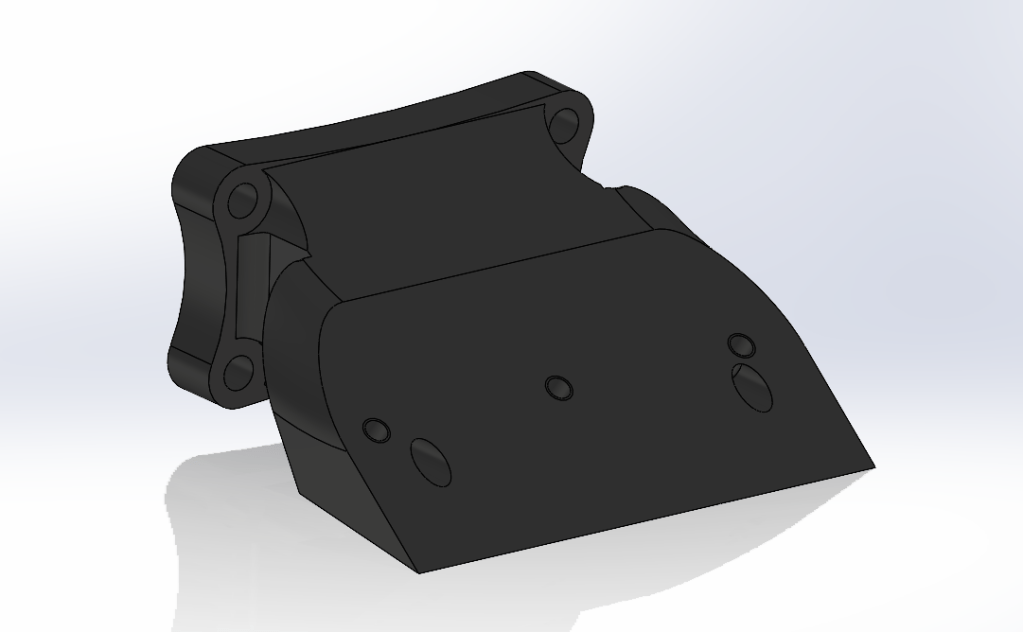

The next important attachments to make were “flexlets.” Inspired by the Bloodsport team and currently run by Eruption, flexlets are based on the idea of using the natural flex of a material to create passive tension that pushes the wedge into the ground. In this case, I printed a TPU mount and attached it to AR500 front wedges. The TPU is designed to angle past the natural low point of the robot (i.e. when you lift it off the ground the wedge reaches lower than the robot) and as the robot settles on the ground it leans forward, pushing back against the TPU chassis. Since the TPU isn’t strong enough to lift the entire machine it instead just pushes really hard against the ground ensuring that the wedge is as riding flush to the floor with no floppiness. You can see the effect of this with how Vorion is able to gather little material bits off the garage floor.

In theory all of this was to address the next issue Vorion had against Emulsifier which was their forks touching the body of the machine first. From earlier fights its known that there is a limit to how long a fork can go before it becomes itself a target. However, you still have to control the ground game otherwise you risk being beaten very swiftly. Therefore, having low surfaces all across your machine to ensure you either tie or win every interaction is the only reasonable way. Hydra (above) is famous for having many small wedglets on the front to ensure that whomever it runs against they won’t be able to completely under the machine. If it works for a large control-heavy machine then it seems reasonable to try it on a much smaller one.

After those changes were made, new lifting arms and hoops were designed. These hoops were longer as they were designed to reach further over the rear of the machine and ensure that even if it got tilted any further it should still be able to self-right. Think of it as increasing the runway on an airplane; the longer the runway the more time a plane has to properly land. In this case think of the hoops as increasing the distance back the machine could be tipped without rolling onto its weapon and getting stuck on its face.

After that a bit of paint was added. Since the Leatherbacks are designed with red the blade and robot got red claw marks to match.

Shortly before the event, we were given our opponents and Vorion drew Pepe Silvia as first fight of the tournament. After its bout against Pepe at Motorama, there was some ideas of how to handle the crazy beast. Since the horizontal wedge was where Pepe grabbed and threw in the previous fight, it was time to try a fork configuration so that Pepe should not, in theory, hit anything but the weapon. After making narrower bracers, guides were welded to the side of the bracers to funnel Pepe into the weapon. They were designed to be very low profile as Pepe could easily tear them off if struck from the side. The welding process for this was a fun game of thermal management. To ensure that the forks stay level, they were lightly welded in place then the part heated to tune how close it lays to the ground.

Once done, the robot was painted up and prepared for competition!

NHRL June Teams 2024

You can read about the event here. Here were some of the key takeaways:

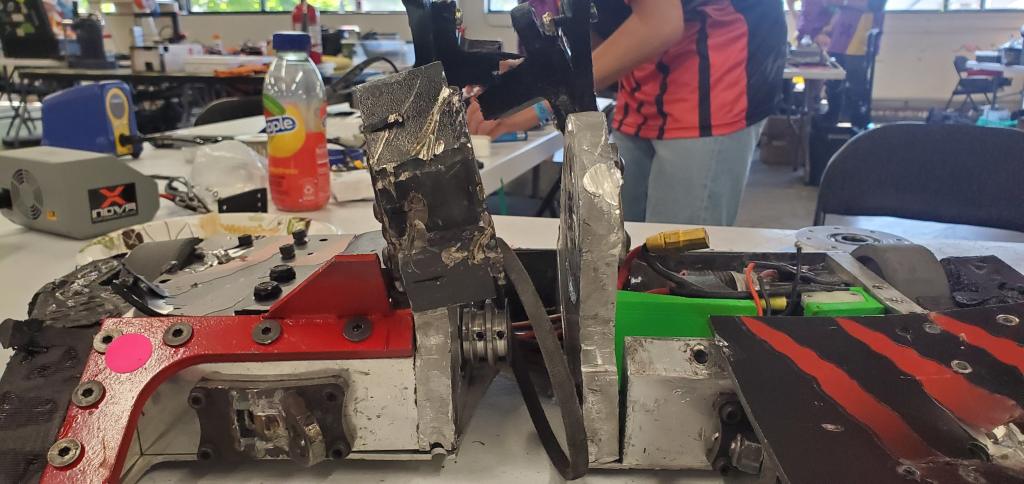

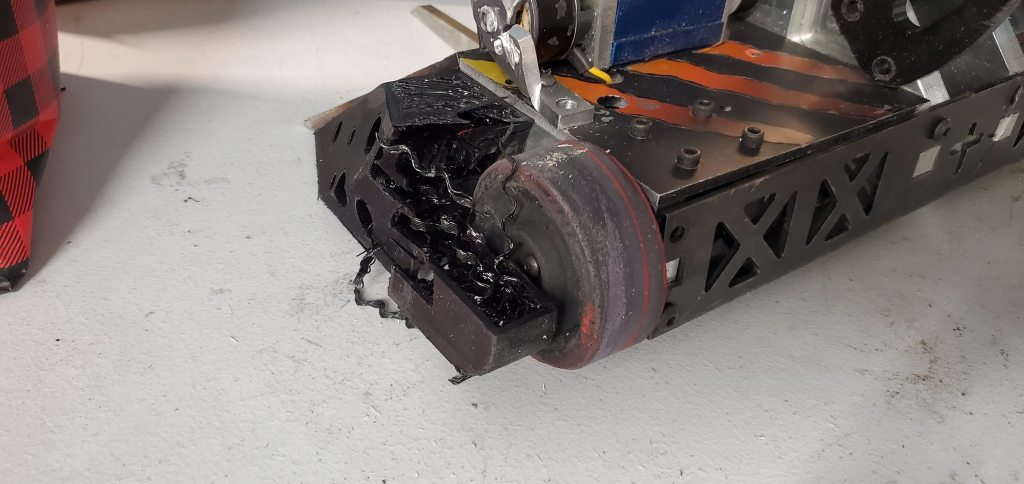

- Despite the incredible damage from Pepe, the strategy did do its job though it was still limited. Later on in the day I was able to get a view of Pepe’s drum and there were distinct marks of red wearing on the body of the drum that matched the red of Vorion’s weapon. Presumably Vorion’s weapon did reach beyond the teeth of Pepe into its body but failed due to the TPU body actually being a few inches deep meaning Vorion was unable to reach the valuable insides but instead was in the perfect spot for Pepe’s enormous blades to catch and throw it. In the future the only method of attack will have to be going for the legs (again).

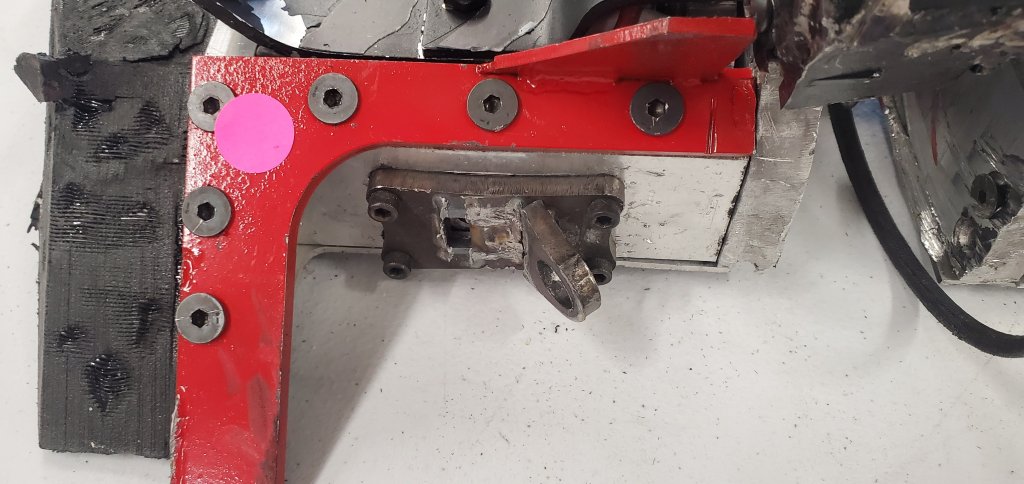

2. The removal of the center wedge link from Phenomenon version 1 weakened the chassis’ side-to-side retention. Though it has only happened to Vorion against absurd loading power of Pepe in arguably its weakest setup to that shot, it was concerning seeing it happen. Increasing the diameter of the retaining bolts of the shaft from 1/4-20 to 5/16-18 would certainly help, but it also indicates the benefit of some secondary retaining feature in case the bolt heads are struck the same way Pepe did to them.

3. The electrical gremlins struck again. Even though bot 1 was a write-off after fighting Pepe, the second machine was in pristine state to fight CRACK? but during the fight the bot went crazy and lost electrical control for most of its systems leading it to crab walk. This is not to say CRACK? was totally ineffective as it did inspire the short somewhere in the system, but the machine looked good mechanically so it was very frustrating seeing it demonstrate seemingly invisible issues. This will require more testing at the Hive.

As a consolation for the disappointing end, Vorion did look good displaying with Jubileu (left) and Floor Letter Word (right) at the GSCRL June Jumble while Cattywampus fought.

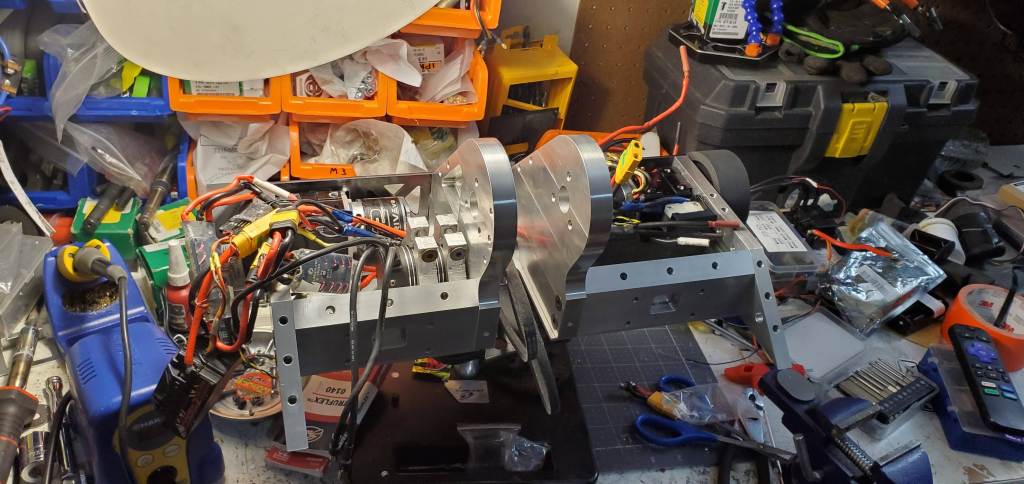

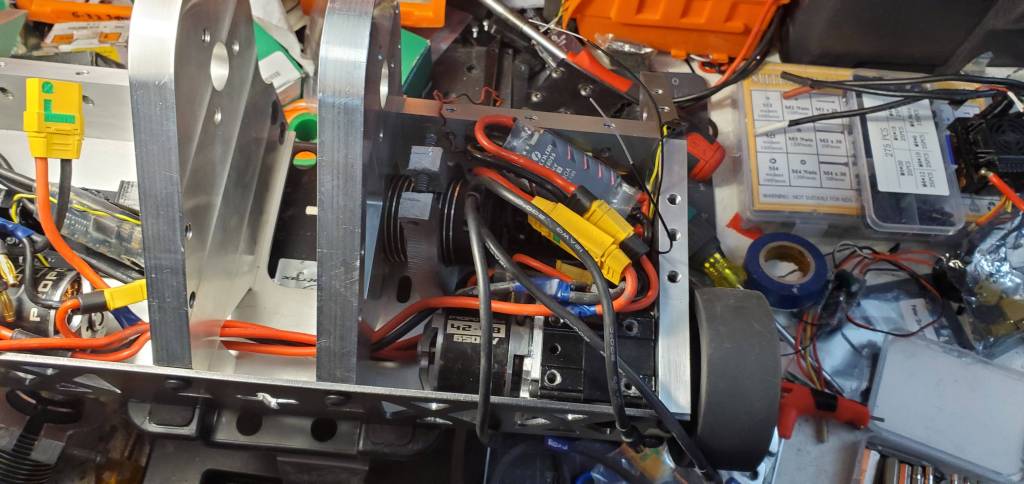

Another Vorion

After losing the first Vorion (the same that ran all of 2023), it was time to replace it. With the first one I used my own CNC router to cut out the large frame rails of the machine then used lasercut components (the tops, bottom, and backplates) as templates to drill and tap holes through but this process had issues. First, the time to cut the frame rails took a very long time on my router which also generated lots of heat as the tool rubs against the part and the deeper you go the more difficult it is to clear out the cut material causing even more rubbing and even more heat. Second, ensuring the holes were perfectly aligned was hard and even with care it frequently was misaligned which caused issues allowing other backup copies to correctly line up. In the second Vorion (which was partially outsourced) the assembly went together very quickly and all the parts fit well. Even though it would take more cost to build the parts, ultimately the headaches were gone. Think about it like this: if I were to pay myself an hourly wage to make this would the tradeoff have been worth it? The answer was no so these parts were outsourced which allowed the new machine to come together within two nights of work.

Hive Testing

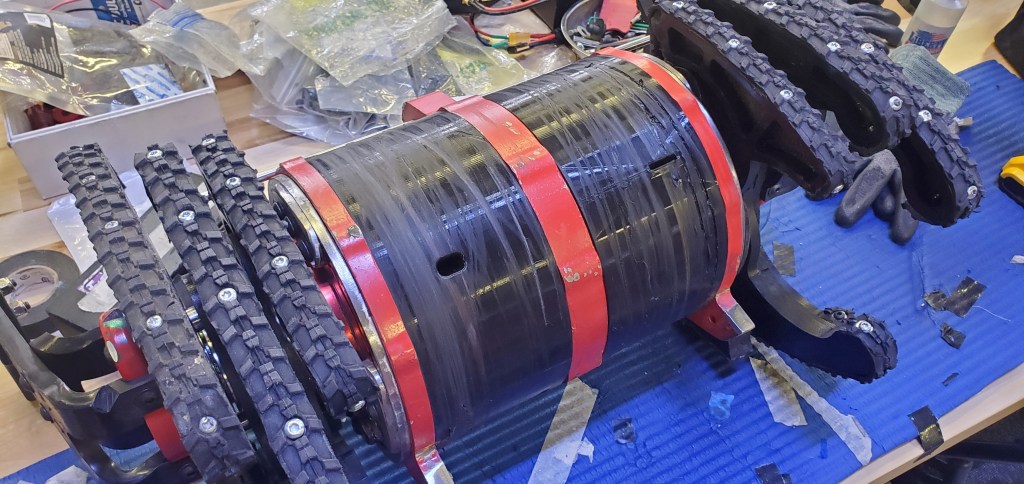

Vorion and Phenomenon went to the Hive to test different rear hoops and disc configurations before Finals. The main issue to be tested was how well would the robots self-right in most scenarios beyond any use of the lifting arm.

The big observation made was between disc shapes. Since 2022, the single tooth cutter blade has been the primary weapon in the weight class due to its versatility (especially against horizontal spinners), lower weight, and devastating energy transfer ability. The downside is that its profile is very hard to get self-righted from as more of its area lies against the floor. In the images above you can see how this distance is considerably more than the rounded blade from 2021 which has a much easier time rolling across the ground. In the gif below you can see how Vorion can work well even without the hoops on its back.

The downside of this blade is it has an incredibly high moment of inertia meaning that it will lift up the side of the robot even while spinning at a relatively lower speed. This is difficult as it limits how much precise control I can maintain during a fight which is critical against very good vertical spinners and control bots in a match. Its greater weight also means that the machine is very tight on weight which leaves less flexibility for changes according to the enemy’s plans. While a good idea, it means this will be shelved for Finals since I want as little variance in behavior as possible.

Tire Repair

After testing, I saw that the Robocore wheels had been worn down dangerously low. I wanted to preserve the aluminum hub in the center so I needed to add some tread to it. Based on knowledge learned from Fracas earlier in the year and inspired by Sawblaze’s own success on this, I asked Jamison Go for some direction on it then figured it out from there. Using a SpunSpoon (which I highly recommend for mixing things) and some Vytaflex 60 mixed with black mica powder a new tread was made and cast over the Robocore wheels using a mold. After applying mold release, the material was poured in and left to sit for a day before being attached to the robot.

After some light testing on concrete (which did a good job removing the smooth outer layer and making it more rough and grippy) the wheels showed great abrasion resistance after about two minutes of driving.

Last Finals Prep

Since the robots were mostly together since the testing at the Hive, there was few things left to change. The sticker graphics tried at the beginning of the year came back to decorate the front wedge pretty painlessly and a fork configuration was setup to fight against first round opponent Pegasus. A guard was also made to defend the lifter motor from glancing impacts.

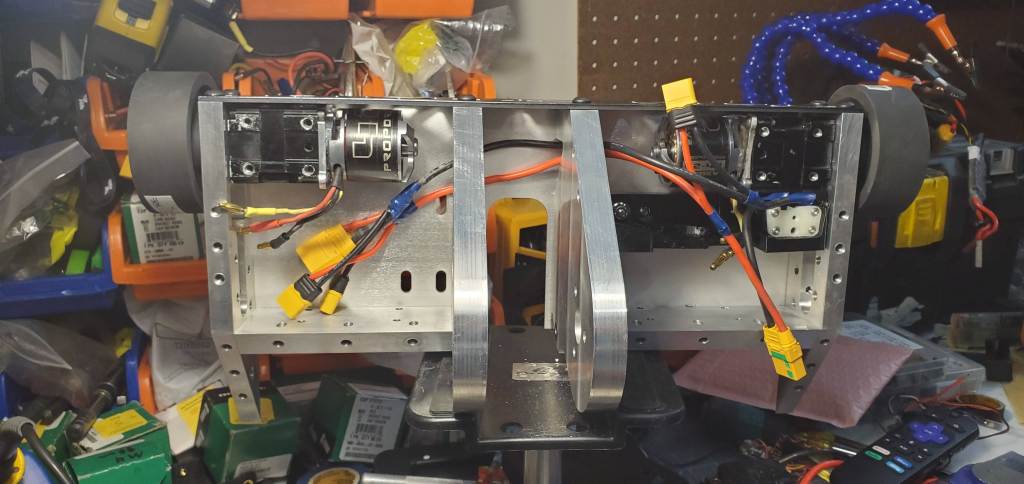

NHRL Finals 2024

You can read about the event here. Here are the key takeaways:

- The pulley system takes up considerable space compared to the hubmotor system in Phenomenon. Due to having a large motor and its controller inside the chassis, the right side tends to squish the electronics and create stresses on the wires which wasn’t helped by adding connectors for greater modularity. As a result, Vorion’s loss to Pegasus wasn’t mechanical in nature but instead a single wire from a drive ESC pulling out, shorting, and then detonating the inside of the machine. Afterwards all mechanical components were still functional so it was very annoying.

- The radio system needs to be checked again. In both of its fights it was plagued by radio issues before, during, and after the fights. Though it showed no issues at testing in the Hive, there was clearly some issue either in robot assembly or in venue which created lots of interference. This interference was surprising and just as frustrating as, once again, electrical issues were exposed instead of the mechanical improvements.

While it is important to note that these changes are also important to find and address, these are not the dominant concern of a combat robot builder most of the time. The mechanisms are the real heart of these machines and the learnings from Motorama and March NHRL were mechanically based so these are the ones which I wanted to address and improve. While there was damage taken on Vorion during the event, none of this was unexpected or wildly different from other fights in the past. By contrast the intended upgrades such as the fork configurations were not tested and therefore remain unknown. This means one thing…more fights! Instead of hanging back and waiting six months between qualifier to Finals this means Vorion needs to be tested more often to find these issues. There’s plenty of other ideas for this machine to try out so hopefully those will be seen soon.

See you again in 2025!