The preparation for the October begins the moment that the fight with MegatRon in June ended. Though Phenomenon came away from the fight largely intact, there was distinct damage done that had to be addressed.

MegatRon’s shot to the fork and lifter revealed their frailty. Not to downplay MegatRon’s power, but in a fight against even more violent weapons such as drums or beater bars this simply could not stand. The forks on Phenomenon are its first line of offense and defense so they must be treated as such. In fights against old drums such as Yahoo back in September 2023 as soon as the forks fell off there was no way to corral the opponent and the robot had to take direct damage.

Similarly, the lifting arm acts as retractable ground game and, even more critically, as the self-righting system. Originally, when this was directly attached to the output of the lifter gearbox, it meant there were few ways to truly destroy it short of bending it heavily or damaging the gearbox. After Undertaker actually broke the output stage of the gearbox against Vorion in February it was essential to make this offset. By adding more complexity while still having to maintain weight it led to a very weak support for the arm that could easily be destroyed. Both of these would have to be addressed.

First thing to do after bringing it home was to use the welder to extract the screws. Once all the sheared bolts were extracted, it was time to bring it to the Hive for testing!

Summer Testing

Most of the summer testing went towards Vorion so it will be covered as we approach the Grand Finals but Phenomenon still had to stretch its legs.

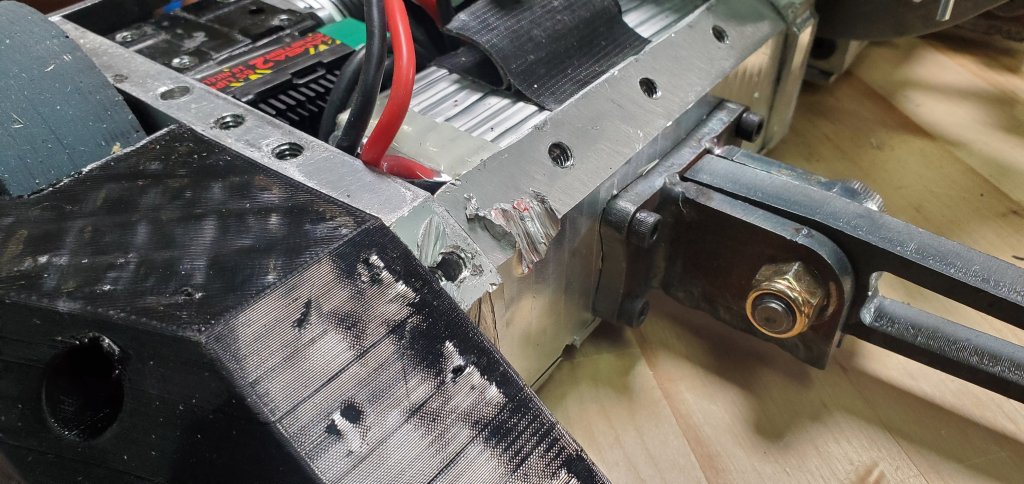

Even in that brief hit, the lifting arm mount sheared off. This type of failure underscores the need for a much better solution.

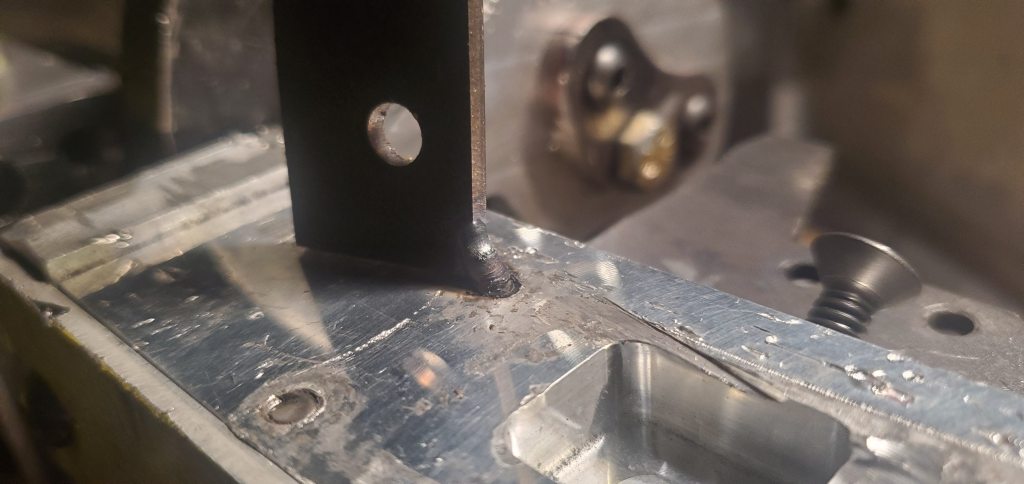

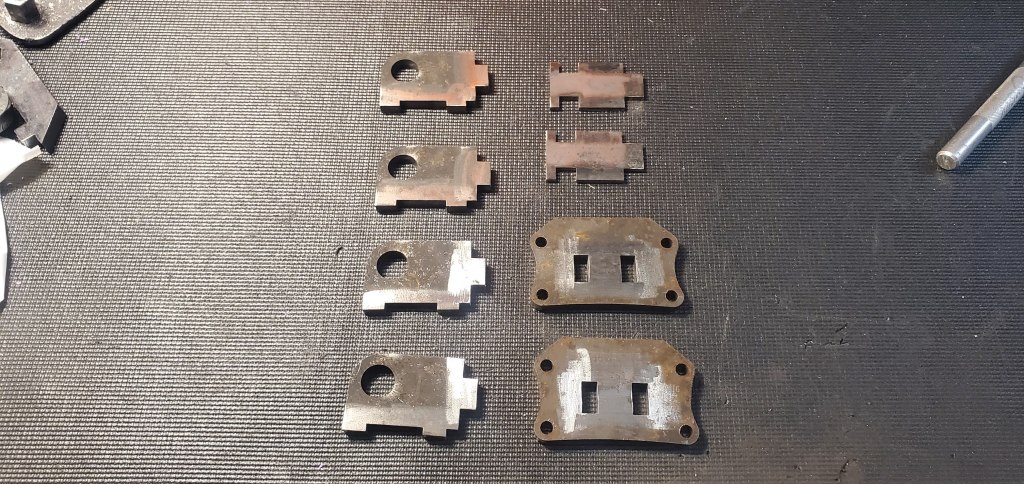

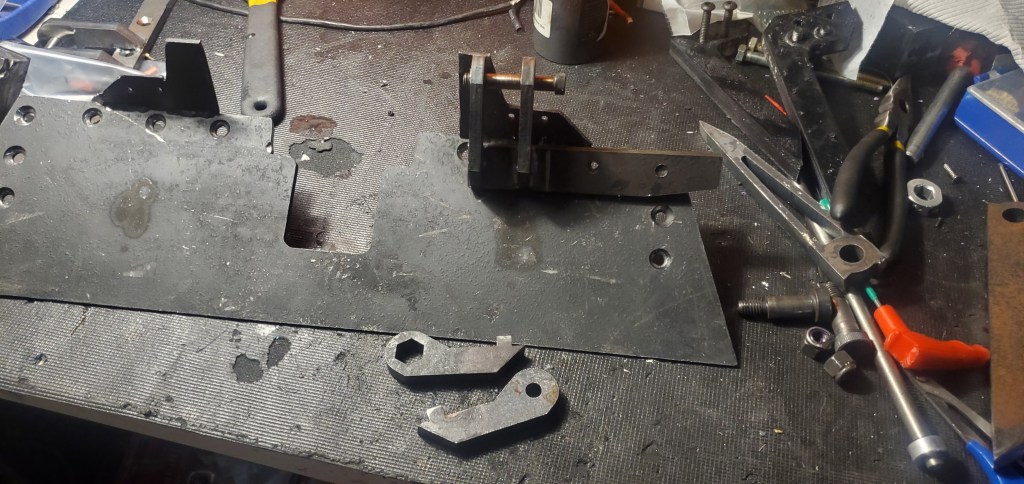

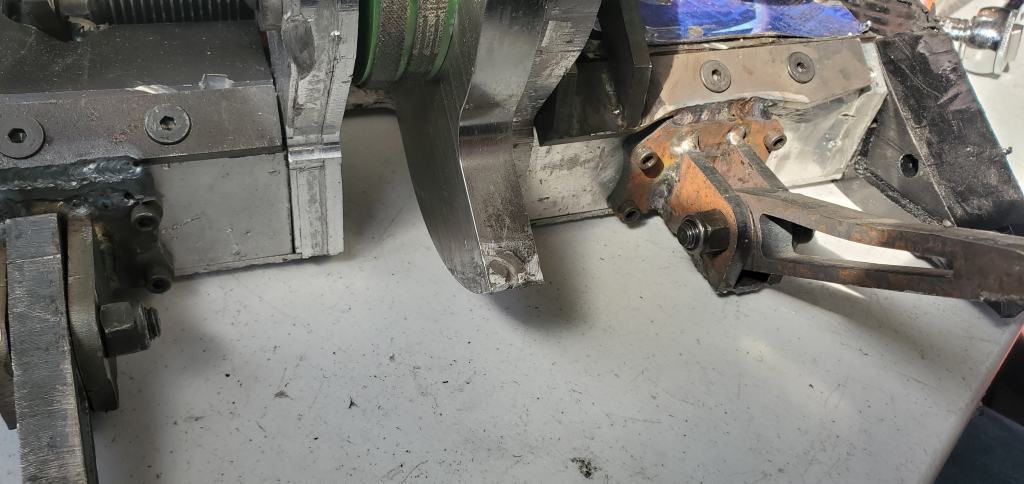

After a quick order from SendCutSend (#notsponsored) the AR500 mounts arrived then were prepped and welded.

Weapon Update

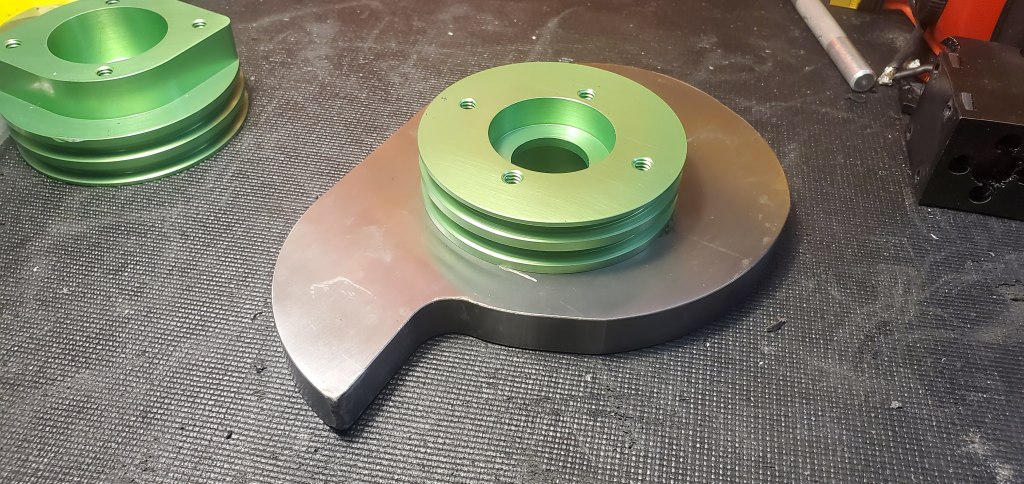

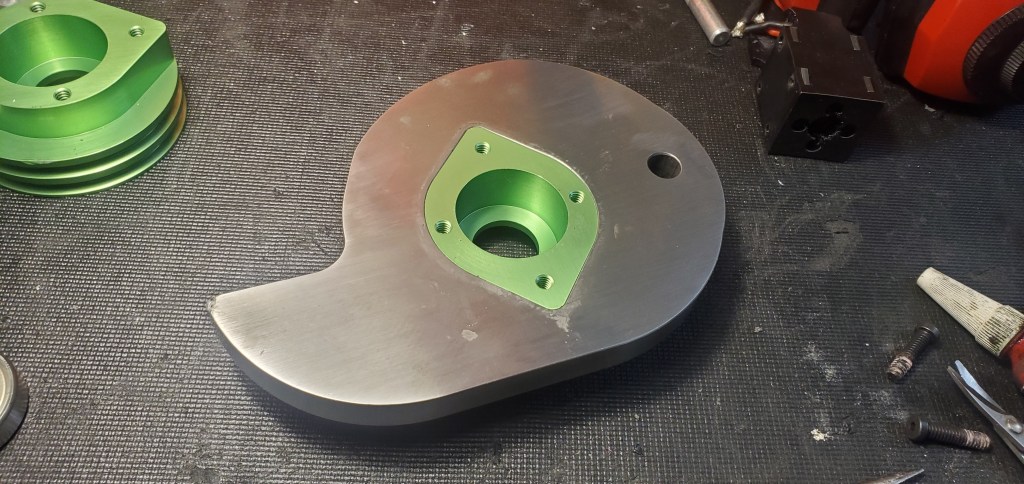

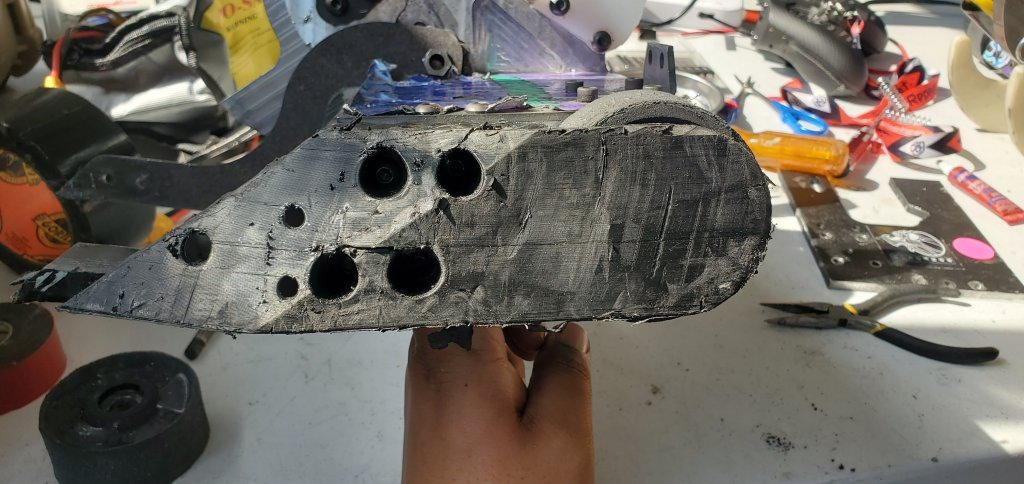

The other surprising find from the testing was an exploded ball bearing in the weapon hub. Back in 2024 the weapon hub switched from needle-roller bearings to ball bearings but to use the previous discs it meant the weapon-side of the hub had to be bored out to fit the ball bearings. Sadly that didn’t leave much material to support the bearing. Initially this was acceptable as the FEA suggested it was still strong enough to handle the forces but over time the aluminum slowly expanded as each time the robot hit something it transmitted force through the hub against the bearing which would gradually squished the softer aluminum. Though it lasted awhile, it was clear the old hubs weren’t going to last much longer so it was time to move on.

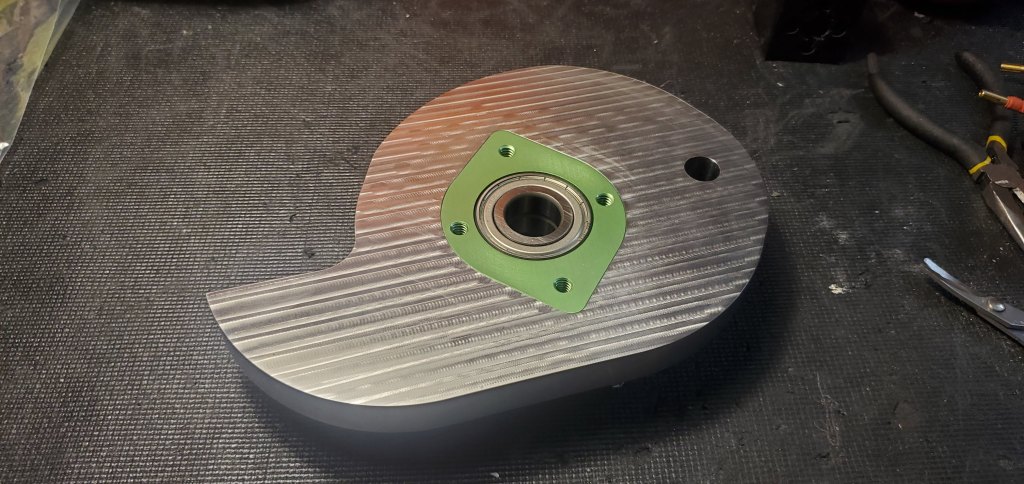

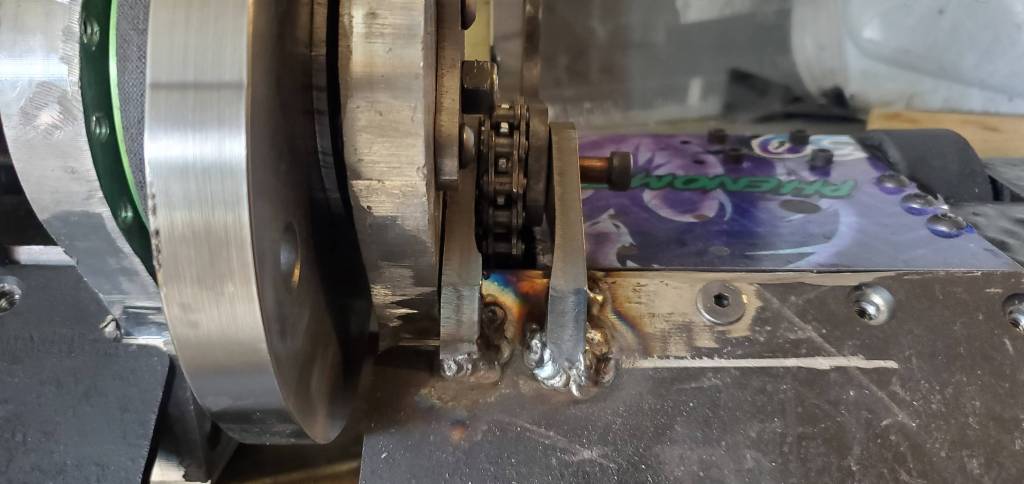

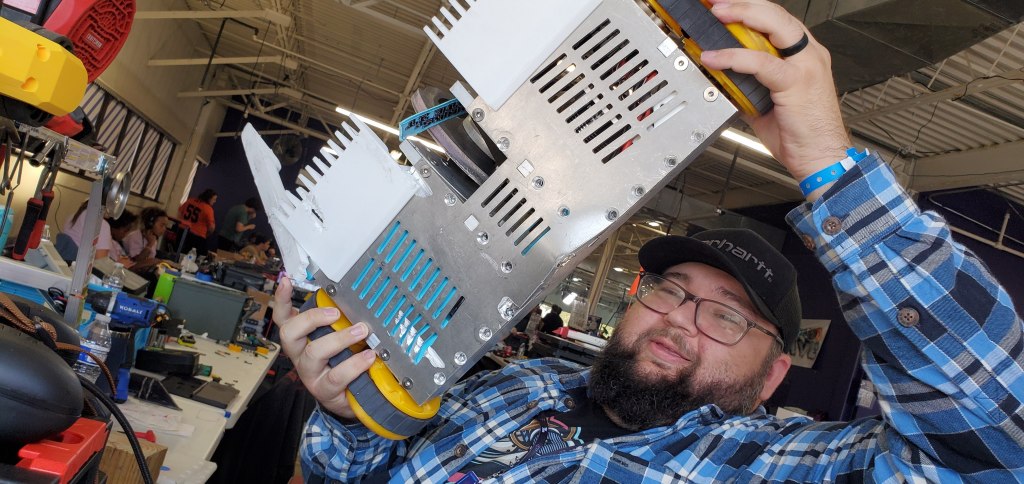

Due to the poor results of the hubmotor thus far it was time to pivot. The blades on the hubmotor are 0.625″ H13 tool steel at 48HRC which makes them the heaviest and strongest blades in the fleet. I theorize the extra thickness (from the usual 0.5″-0.6″ blades) meant the Moment of Inertia was too great for the hubmotor core to get up to speed so it created very poor performance in combat where you repeatedly go from a dead stop to top speed as fast as you can. While this indicated the needs to use the blades on something else anyway, the pill-shaped mounting pattern used in the hubmotors meant it was not designed to work with the existing pulley hubs so it required a new solution. Fortunately that was exactly what was needed anyway as now there was plenty of material to support 3x (from the previous 2x) ball bearings. Once pieces arrived from LT Century (anodized green to match Phenomenon’s colors) it took only a few minutes to assemble them.

Lifter Support

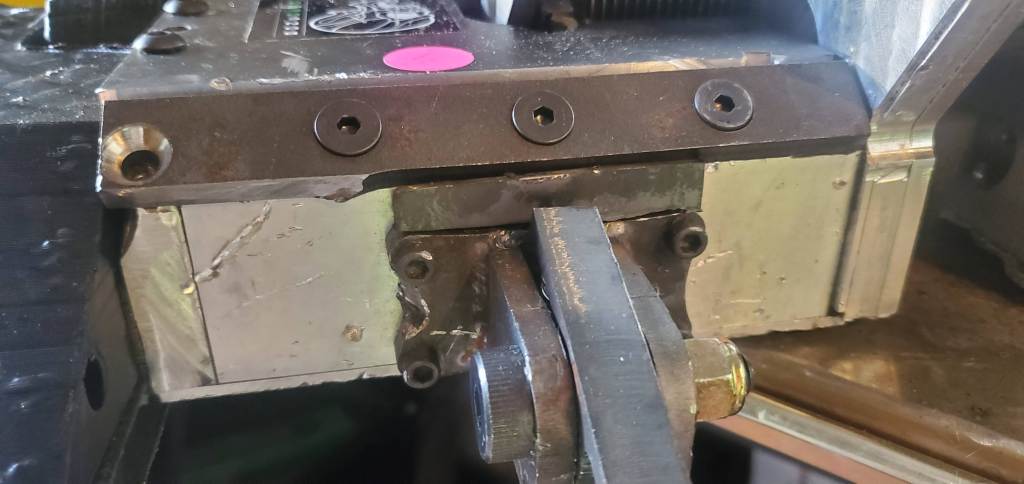

The first part of the build…was better tools. The small desktop drill press was simply not enough to countersink AR500 or drill holes in mild steel well. After a few weeks of stalking Facebook marketplace (#notsponsored) I found a deal for a floor drill press and hauled it home. It wasn’t an easy experience getting it setup but it got there.

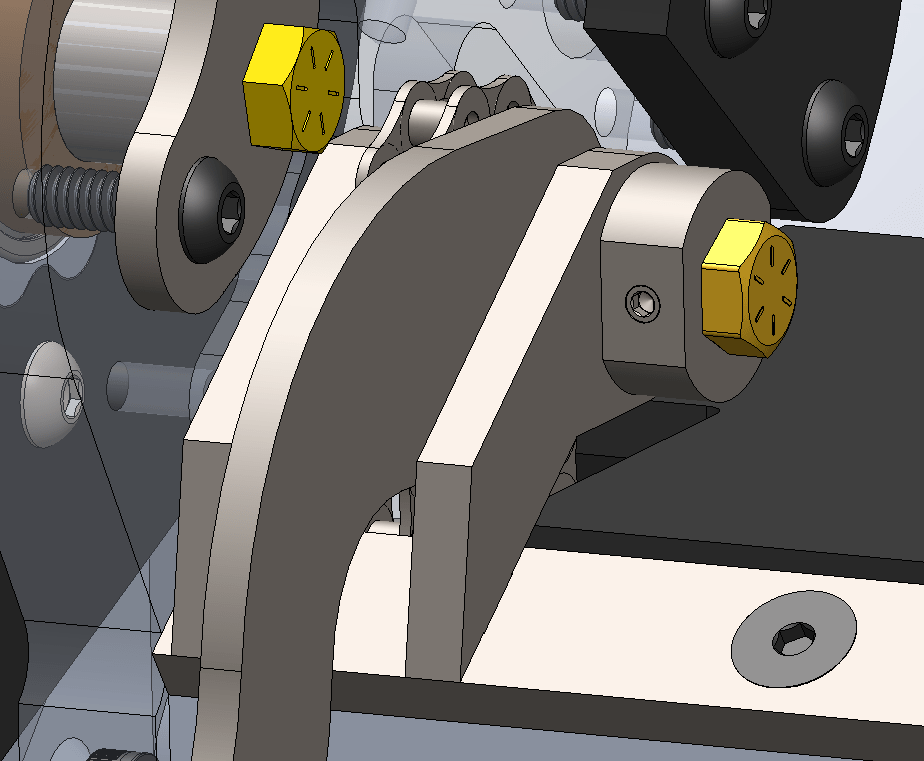

A new mount was then sketched up and fitted to the CAD model. This would use the same 5/16″ OD shoulder bolt used previously by threading it into a weld nut attached to the far side upright. To ensure it doesn’t rotate out during use, a piece of mild steel was welded to the near side upright where it would be drilled and tapped with a 10-32 set screw. After creating a groove in the shoulder bolt, the whole assembly ensured the bolt was now radially and axially constrained while still being fully removable thereby having both serviceability and strength.

A chief constraint for the lifter support was maintaining all the same positions as before. Like the designs before it, this robot was designed to be backwards compatible to previous iterations to maximize versatility and spares. As such, this mount is simple by bolting over the mounting places once used by the front wedge. Its geometry is merely welded mounts designed to hold the pivot shaft in space the same distance as the cantilever mount and top mounted gearbox once did to ensure the arms themselves still function the same way. With the designing done, it was time to prototype!

Despite utilizing tabs to key the uprights in place, it was tricky to ensure alignment. A 5/16-18 nut was welded into the far side upright for the shoulder bolt to thread into and then the bolt was used to align the parts during welding. Unfortunately, welding puts a lot of heat into the target material so it didn’t take long for the mount to warp. By using the torch on the other side I was able to use the heat to balance the internal stresses of the material similar to Matt from Allweld in the Skorpios Builder Blog. After cooling it was fairly straight so the process continued. After drilling and tapping the retainer on the new drill press it was welded to the near-side support. A groove was then cut into the shoulder bolt for the set screw and then attached to the robot. Seems to be functional!

Even more difficult than welding the attachable lifter mount was attaching it to the horizontal wedge. Since the wedge uses the same mounting position as the lifter mount, there wasn’t any way to keep both functional at the same time so the mounts had to be directly welded to the wedge itself. Unlike the mount, the wedge was not designed to have the uprights so this required a lot of free-hand work to hold it in place for welds. Another factor I realized was I had messed up the thickness of the uprights so now I had 1/2″ pieces instead of 1/4″. In this case, it was actually preferred over the thinner ones as the mounts would be tied directly to the horizontal wedge (therefore receiving all the energy from a horizontal impact) the thicker material means a wider and stronger support structure for the arm. To use these while also maintaining the correct spacing of the other structures there was only one solution: grinding down material. With patience and lots of grinder dust, the thicker pieces were ground down to 1/4″ thickness near the arm mounts but 1/2″ where it meets the wedge. Using the same method as before with the weld nut and shoulder bolt as aligning tools and holding the lifter arm taught, the uprights were welded into place. Later the set screw retainer was welded on.

Less than a week before the competition, I learned that Phenomenon would be rematching Touro Feather after losing to it back in 2023. Back then Phenomenon’s drivetrain wasn’t as stout as it is now so it was a frustrating loss that I hoped to avenge myself in. Additionally, it would be a great test for the forks and the catalyst for the last critical step improvement: the support superstructure. By tying in not only the 10-32 front-mounted threads but also the 1/4-20 angled top pieces there is now a 3D structure to support the forks. Think of it like this: to knock them off before you only needed to break 4x screws all in one flat plane; now you must break 7x screws, 3 of which had greater holding strength and in a different plane from the first 4x. The new plane to shear all of the screws is an angled plane that cannot be easily struck. In short, this was the best possible way to resist a massive drum or beater bar short of a redesign.

Its important to note that while the lifter side was designed for this (the fork mount and lifter mount naturally intersected due to extra material built into them) the left side was made from older forks and older braces so it had to be bridged using a 1/8″ piece of mild steel. Its likely not as strong as the lifter side, but it is still considerably stronger than it would be without it.

Wheel Remolding

Using the same tire repair method shown here, the old rubber wheels were once again treated and recast with Vytaflex 60. To ensure a slightly longer wear life and a bit more speed the diameter was upped from 80mm (3.15″) to 3.25″.

Event

After arriving late Friday night and heading straight to the hotel, we arrived at 6am to safety the robots and enjoy the beautiful sunrise. Both versions flew through safety and were ready for the first fight against Touro Feather!

Touro Feather

Touro Feather is a incredibly daunting first fight. This robot comes with over 20 years of experience and the pedigree of a champion. It kept up Phenomenon’s 2025 streak of fighting powerful opponents early in a tournament, though this was also where I hoped to break the streak of continued losses. Defeating Touro would set the stage for the rest of the day and prove whether all the small but critical changes would be felt or not. You can watch the full fight on Brettzone here but I’ll highlight the key moments in finer detail below.

Moment 1: Power vs Power

This was a blink-and-you-miss-it start to the fight. Like two samurai quickdraws you get the feeling if either machine approached the other with anything less than weapon the fight would be heavily biased to the other. This moment was also critical because it proved the worth of the improved weapon system; that hardened blade and stronger pulley hub meant the weapon kept going without losing a beat. It’s also cool seeing the robot very cleanly rotate about the weapon axis after the hit.

What also cannot be understated is the importance of the lifter. Two years ago Phenomenon would have been stuck firmly on its face but practice plus hoop geometry meant it took minimal time to self-right and get back in the game. This will become a trend.

Moment 2: The Treads

Before this moment, the treads had been a very consistent solution to wheel repair so to see them come off and potentially give an advantage to Touro was terrifying to say the least. It’s hard to say if there was any difference in its curing process that would have led to material delamination (this part was not recorded thoroughly as it was assumed to be similar to previous batches) but it was clear that as soon as the tread came off and the normal rubber beneath was exposed the drivetrain was more than happy to get to work.

Moment 3: The Wheelguards

After again proving the increased resilience of the weapon (a very welcome upgrade), the wheelguard design was proven. Without wheelguards, a direct shot from a weapon as beastly as Touro’s would certainly have torn apart the wheel at minimum, likely bent the shaft at worst. Instead, the large and squishy TPU wheelguards and shortened UHMW outrigger (shortened to avoid being caught by Touro) took all the shock away from the robot and simply moved it over. Once again, the theory that drums do worse against large flat compliant surfaces proves itself true.

Moment 4: The Forks

Up to this moment, the forks were proving themselves incredibly resilient against Touro when directly lined up. It is only this shot where Phenomenon approaches at an angle where Touro catches the fork and bends it upwards leading to an easy opening. While certainly a bad sign in most cases, its important to remember that the fork assembly was still attached which could be a promising sign for strength. If the fork bent on its own and the structure is fine then that is a huge positive for future plans against beater bars and drums (something tall thin vertical spinners that use ground game are historically weak against).

Moment 5: Lifter as Drive Support

After both treads are off the robot (which I believe Touro was able to snipe in a previous offensive motion), the treads are now too low for the robot to comfortably drive on. If there was nothing else to help Phenomenon it would be a painfully slow and dreadful time, but because the lifter is designed to lift up the nose of the robot a few extra degrees it could lean the robot backwards, rotating more weight onto the rear wheels and letting it drive almost normally allowing it to deliver a massive uppercut to Touro that killed both weapons. The lifter has already proved itself as an MVP element so far, but now towards the end of the fight where both fighters are punch drunk it was critical to have that extra distinguishment to really sell the victory and that’s what it was going to do.

Moment 6: Lifter as Primary Weapon

Phenomenon is not the most distinguished among the other vertical spinners in the 30lb weight class. In fact, its by power the weakest one with the smallest weapon and lowest energy stored. But what makes it different is that it can be understood differently from its peers; it’s not just a weapon delivery system with a backup element but a control bot with a decent weapon system.

This little difference means not only a change in how it attacks, but it also means when push comes to shove it has two weapons to fight you with which means just a bit more complexity than your average fight.

Though Phenomenon and Touro both lost weapons, Phenomenon had a second one to carry it home and carry it did. After not only self-righting the robot and saving the drivetrain the lifter also totally controlled Touro the rest of the fight by flipping it, pinning it, and generally showing more control and aggression.

All of these factors were improved in the offseason and all of these factors came together to give the W.

Winner by Judges’ Decision, 1-0.

Post-Match Damage

Despite all of the energy in that match, I was pleasantly surprised to see little damage on the robot overall. First, you can see how little wear there was on the tip of the blade. In previous fights the tooth wore itself down on large shots so to see it directly hit such a powerful weapon and come away with only small chipping on the edge was a great surprise. Definitely very pleased with the investment in the better blades!

Second, the forks. The forks themselves were pretty beat up but less than I feared. The fork on the right was clearly bent up by the off-angle shot from Touro but I was very pleased to see the superstructure itself was unharmed! This fact now means the next failure mode is the fork itself which is much easier to hone via better geometry. The other fork shows the impact point of Touro’s drum against the current shape; perhaps this will be a good reference in the future.

Third, the side armor. Cutting down the outrigger was supremely important to resist Touro as it minimized chances of catching and throwing Phenomenon. While it was struck (and the bolts bent beneath it) the side armor ultimately did not allow the damage to spread to the rest of the robot. Even with the sparser settings (something like 6 walls, 15% infill) it was clear the TPU was abrased but ultimately didn’t fail.

All in all, very light damaged compared to the intensity of the opponent. A very great result to head into the next round.

Deadrise

After surviving Touro it was on to the next round against Deadrise (the yellow and white machine next to Phenomenon). Deadrise uses the Honey Cracked treads to increase maneuverability which makes it hold a striking resemblance to Emulsifier. With this similarity naturally comes the same limitations and concerns: does it outreach Phenomenon? Could Phenomenon survive a hit from it? This fight would prove whether the initial success against Emulsifier was a fluke or not.

The fight itself was a pretty quick affair, but I attribute much of that to the lethal potential of this fight. There’s no question that the raw energy stored in Deadrise would have easily messed up Phenomenon. That being said, it once again comes down to how the two robots interact. By approaching Deadrise at a slight angle and leveraging Phenomenon’s harder steel forks against the softer TPU, Phenomenon was able to essentially reach around the disk. The other side of that equation was Deadrise being able to reach well into the bot’s frame as shown by it clipping one of the horns during an interaction.

Ultimately Phenomenon’s setup at the beginning led to juggling Deadrise and allowing it to bend the baseplate leading to a tap out.

Winner by Knockout, 2-0.

Post-Fight Damage

It does help taking post-fight damage photos with your pit neighbor! Thanks to Joe for generously posing Deadrise for this!

Phenomenon has little damage to it besides the horn being snapped off. Deadrise had a very bent baseplate with most of the hardware on the bottom being snapped off as well. Rough stuff but Joe got it back together to make a run of his own!

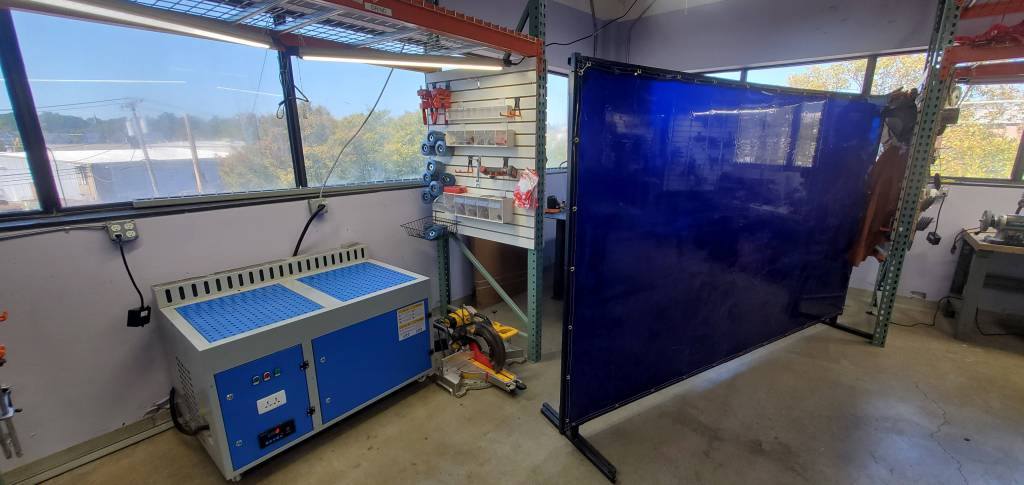

Downtime

One big thing I wanted to shout out was the improved workshop. NHRL moved their workshop upstairs to the area behind the pit desk so builders could very easily fix all of their parts without having to go downstairs and potentially move dangerous pieces of steel through crowds. The shift also increased the total area of the workshop which should help the post-round surges. The press was able to fix the bent fork from Touro back into usable state. Overall a very welcome change and glad to see it!

Downstairs there’s been another update with a learning area for new young builders to try out machines. I didn’t get to see it much in action but it does look pretty good!

For Primetime we received a massage tool kit! I appreciate the nice little touches from NHRL!

Team Skorpios created a vlog that goes more in-depth on the experience. Check it out!

Synthesis 30

Once again Phenomenon starts off Primetime but this time against Synthesis 30. Vorion defeated Synthesis to claim its qualifying spot in February so now it was Phenomenon’s turn. Synthesis’ builder Corey is always learning and growing the design so fighting him is always a comparison of robot evolutions.

Sadly the match was a bit more anticlimactic than hoped. Phenomenon was dominating from the first interaction but sadly the robot died without much fanfare. Congratulations to Synthesis and Corey for the win!

Loss by Knockout, 2-1

Post-fight inspection indicates a bit more damage than expected to the top plate, central rail, and cross brace but nothing more than the robot receives regularly. The big issue was found to be the main ground wire breaking. The brittle wire was under enough tension by the battery connection that it took only a small jolt of movement to have the copper crack and break the circuit. As I was taking the top off of the robot the wire flexed a little thereby sparking and briefly turning the robot back on before disconnecting again. A frustrating way to lose, but a very solvable problem.

Conclusion

Overall, the feeling was hollow optimism after the tournament. Due to the excellent job Phenomenon had done its fights I was overall pleased with the machine and its reliability. Besides replacing the ground wire and relieving wire strain, there were only two noticeable issues: the fork being bent and the weapon going down against Touro. In post-event testing Phenomenon was tested for ~5mins wherein the weapon showed a similar coasting response by the end, potentially indicating a low voltage cutoff on the controller. Its clearly still usable as it was able to work well in testing but it may require a closer look to see why this behavior would happen about 1 minute into a fight with a supposedly full battery.

The positive side of this was that there are now 2x Phenomenons with minimal damage and proven designs. Though the Finals will be full of excellent robots that could all destroy your machine in an instant, I am equally able to say that this is the best version of Phenomenon so far and the version with the best chance to win the event. While there may be the odd little improvements to try out (such as flame protection) the majority of the efforts will go towards rebuilding Vorion from these learnings and those from the summer testing.

Check back later for more event reports! And check out the build logs!

Leave a comment