February 2021

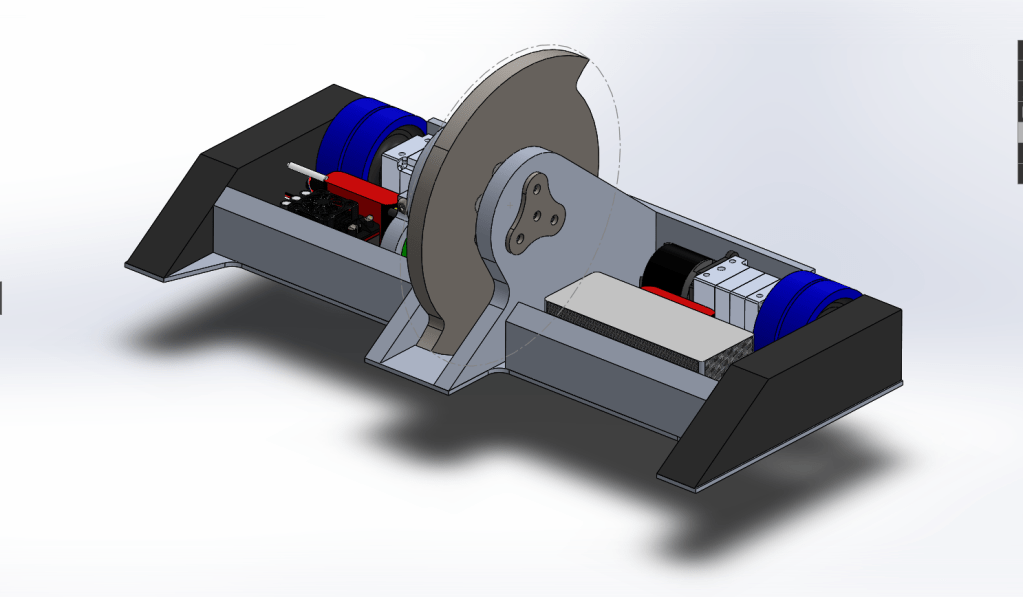

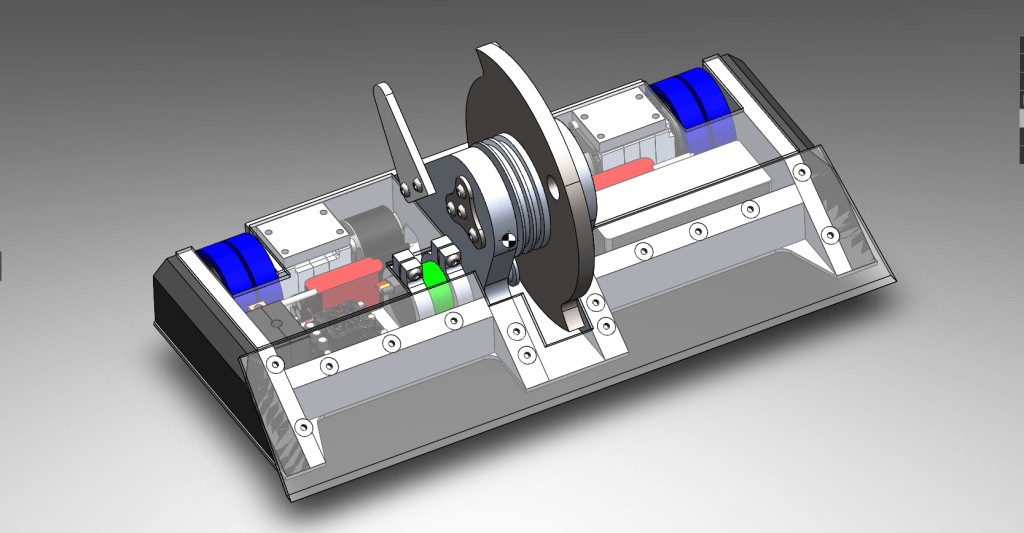

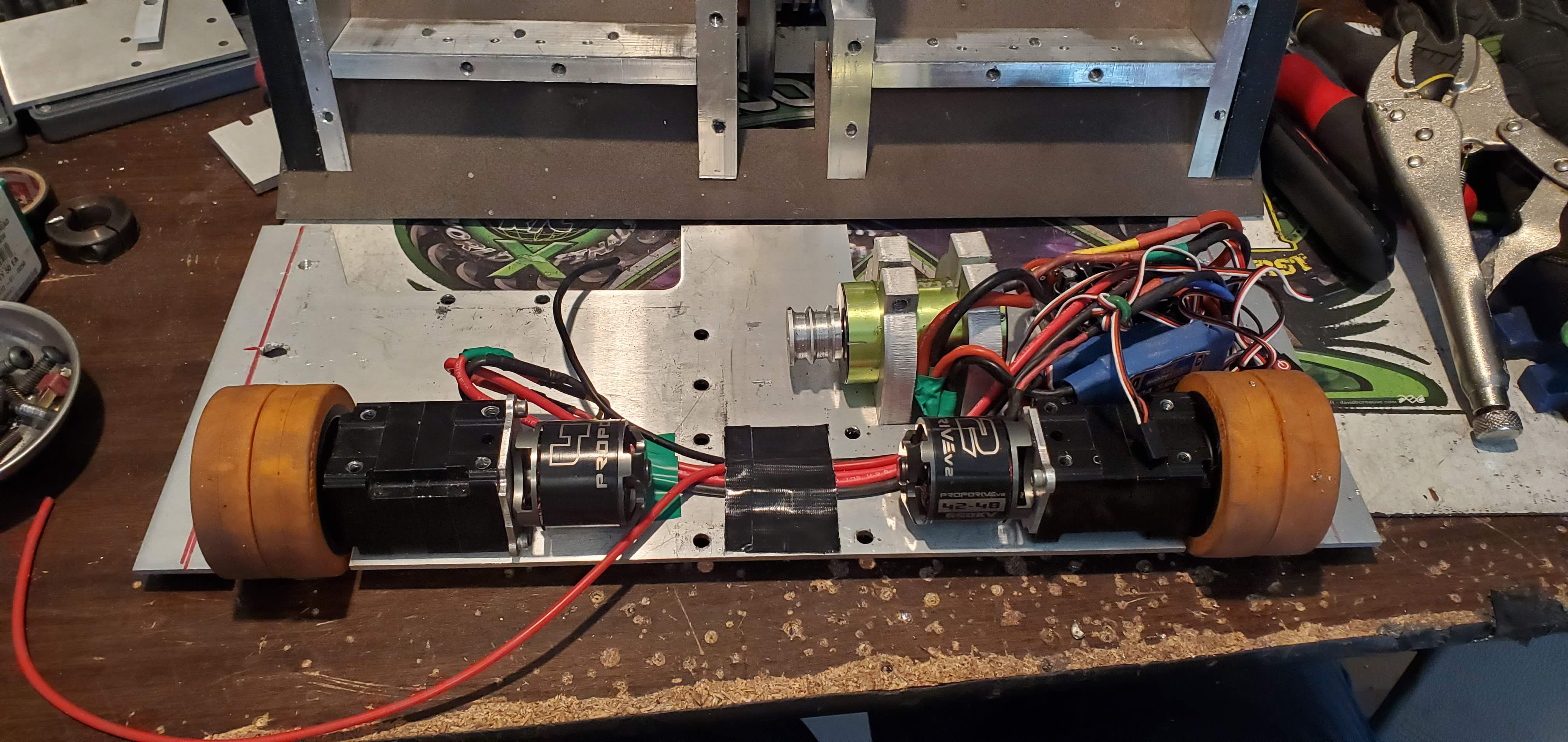

Phenomenon started life with the goal of being a competitive entry into Norwalk Havoc’s 30lb weight class. After watching the February 2021 event I was impressed by Big Ripto’s level of damage, but noticed how Megatron’s ground game was able to counter it. In order to get the best of both worlds, Phenomenon was designed with modularity in mind. The simple design shape allowed the machine to be designed completely over one weekend; a new file was opened on Friday and the first parts were sent out to SendCutSend at the end of Sunday. Much of the design basics such as the drivetrain, battery, and weapon system were leftover components from previous robots Remedy and Tactic with the goal of keeping the cost as low as possible. You can see the first stages of design emerge in the pictures below.

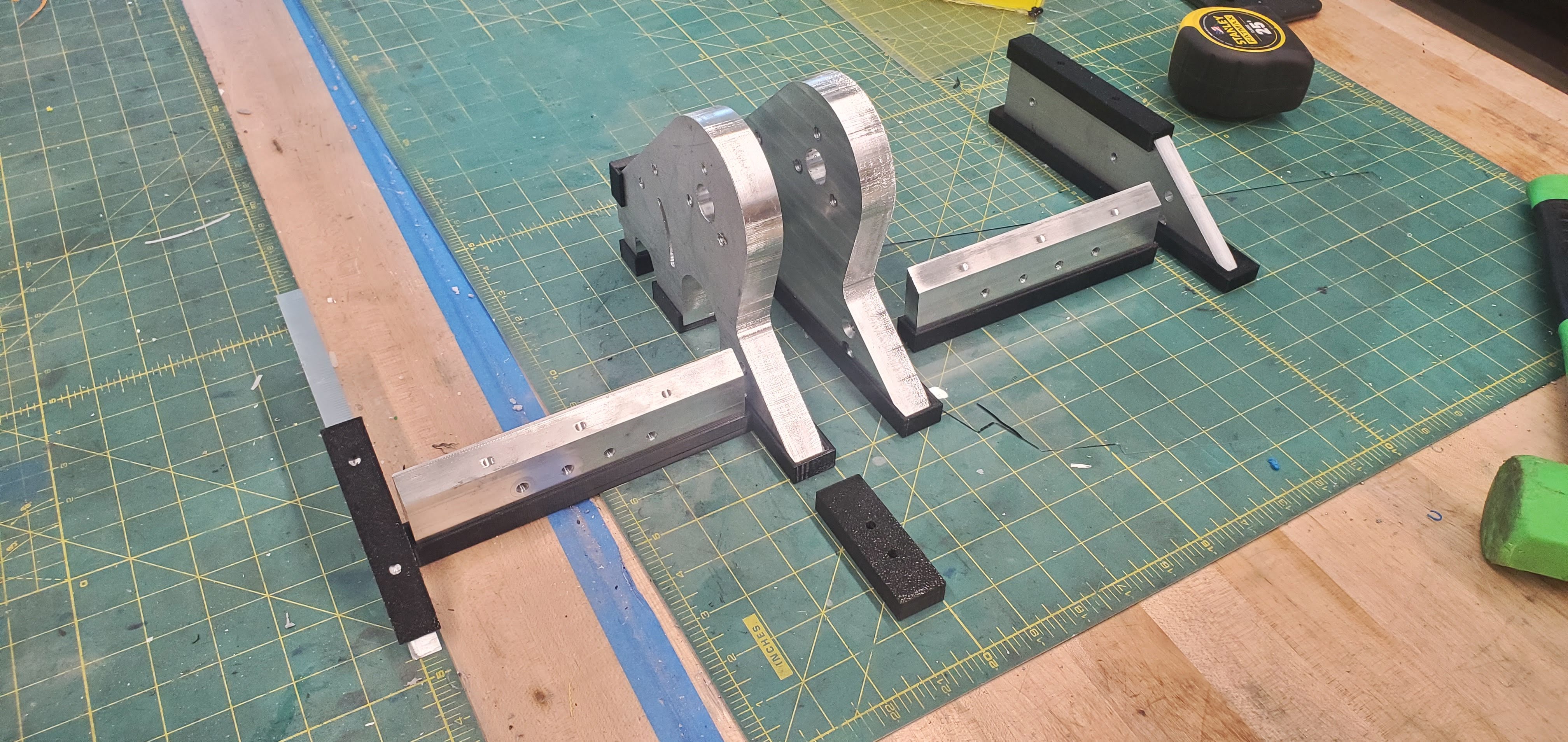

The easiest components to begin building were the outer guards. During my time on Big Dill, I learned how effective ablative outer armor can be for shock absorption so 3/4″ UHMW guards were integrated into the robot so any directy hits to the wheels would be readily absorbed and leave no permanent deformation since the material could be easily cut and removed without any permanent deformation. Since UHMW is also very soft and machinable, this was an easy component to make on the router.

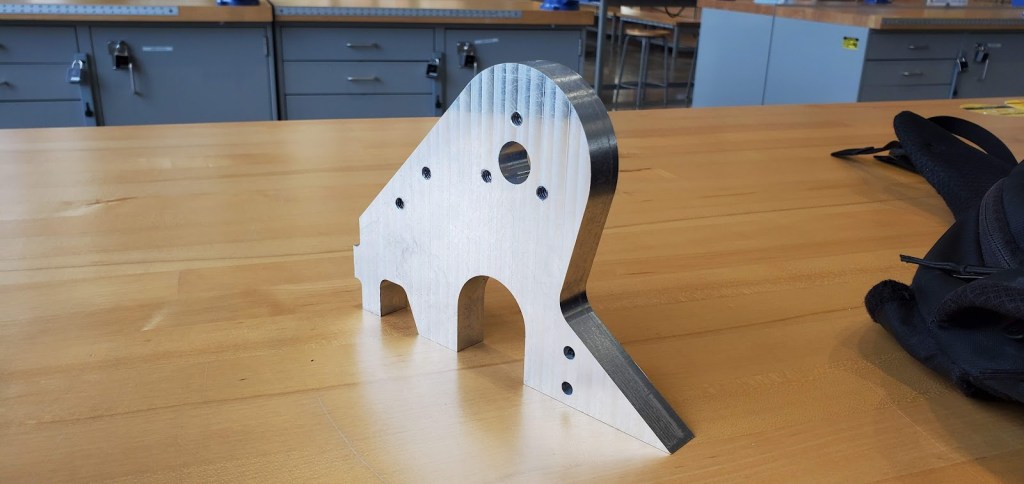

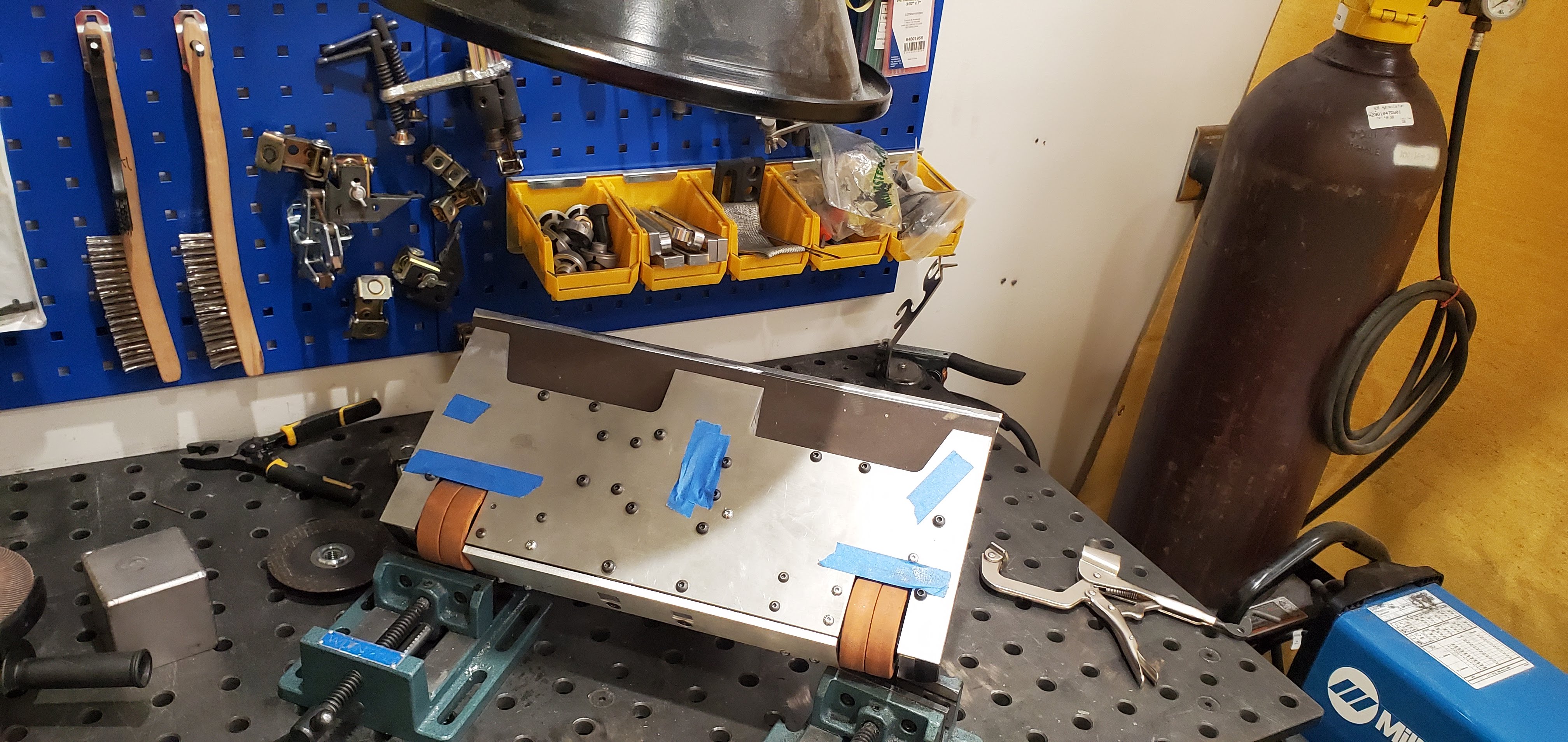

The next step was to make the cross-braces using my job’s Datron Neo. Because it has a vacuum work bed it was very easy to directly route out the 1/2″ 6061 and create pilot holes. Because there was a bevel on the front, I used 3D-printed jigs to hold the piece at the right angle for the drill press. This worked beautifully. Another score for 3D-printing! Now for the other weapon components.

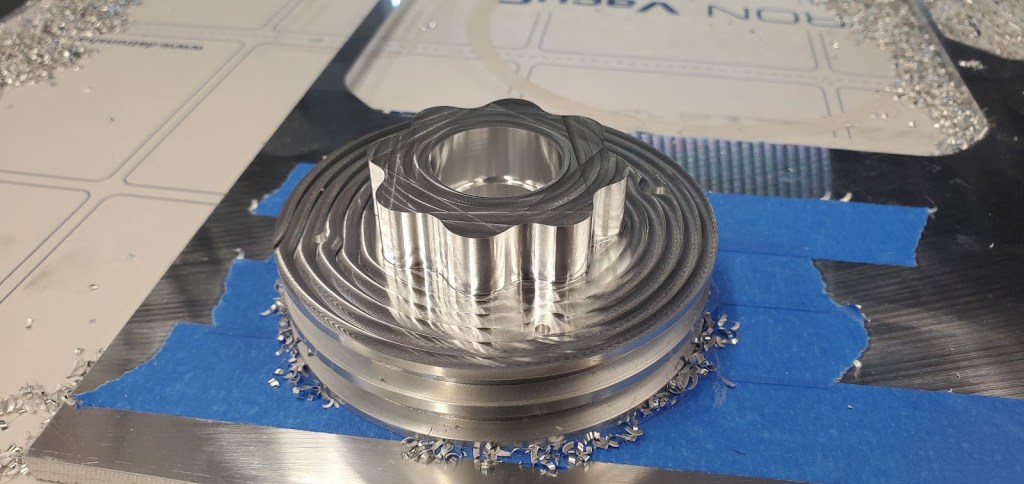

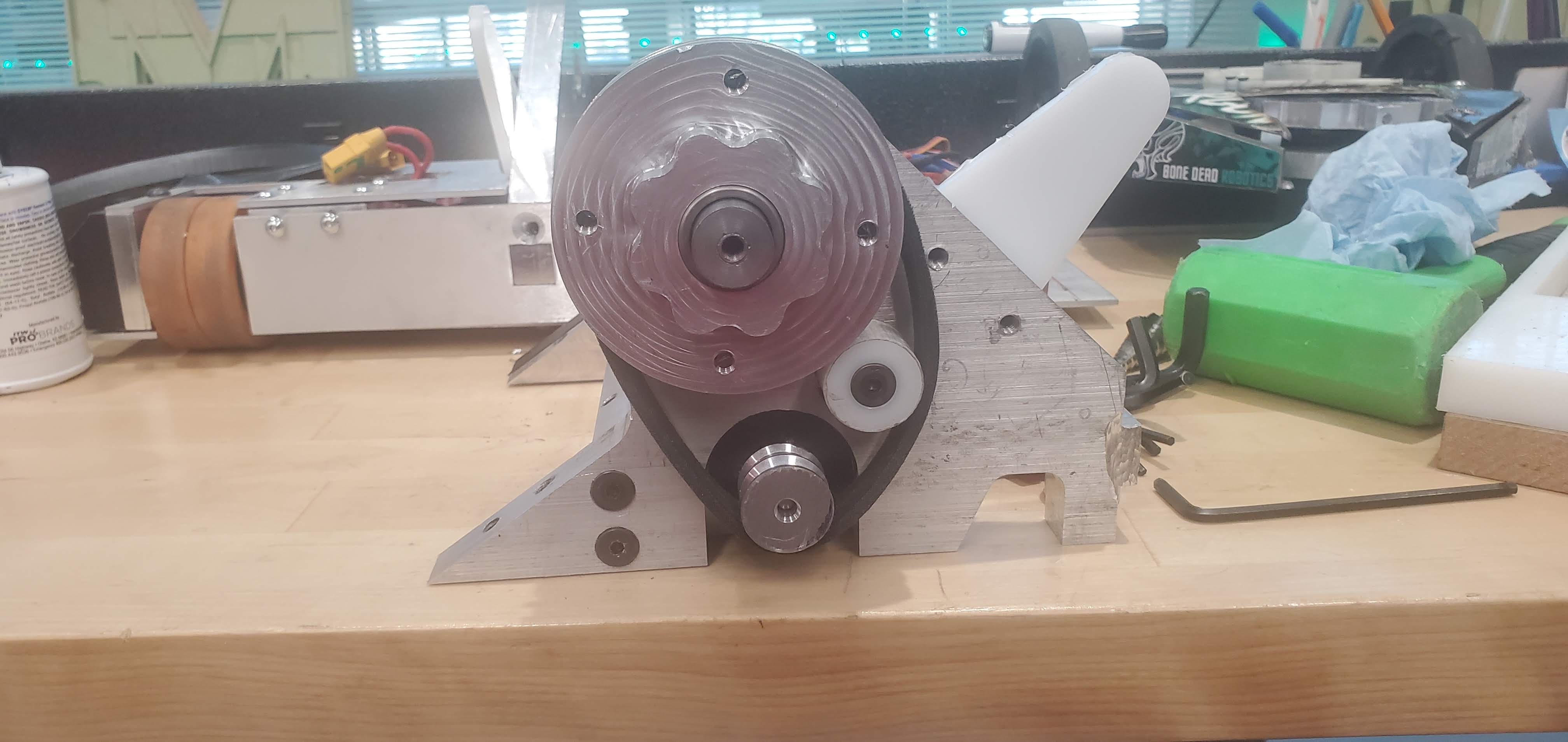

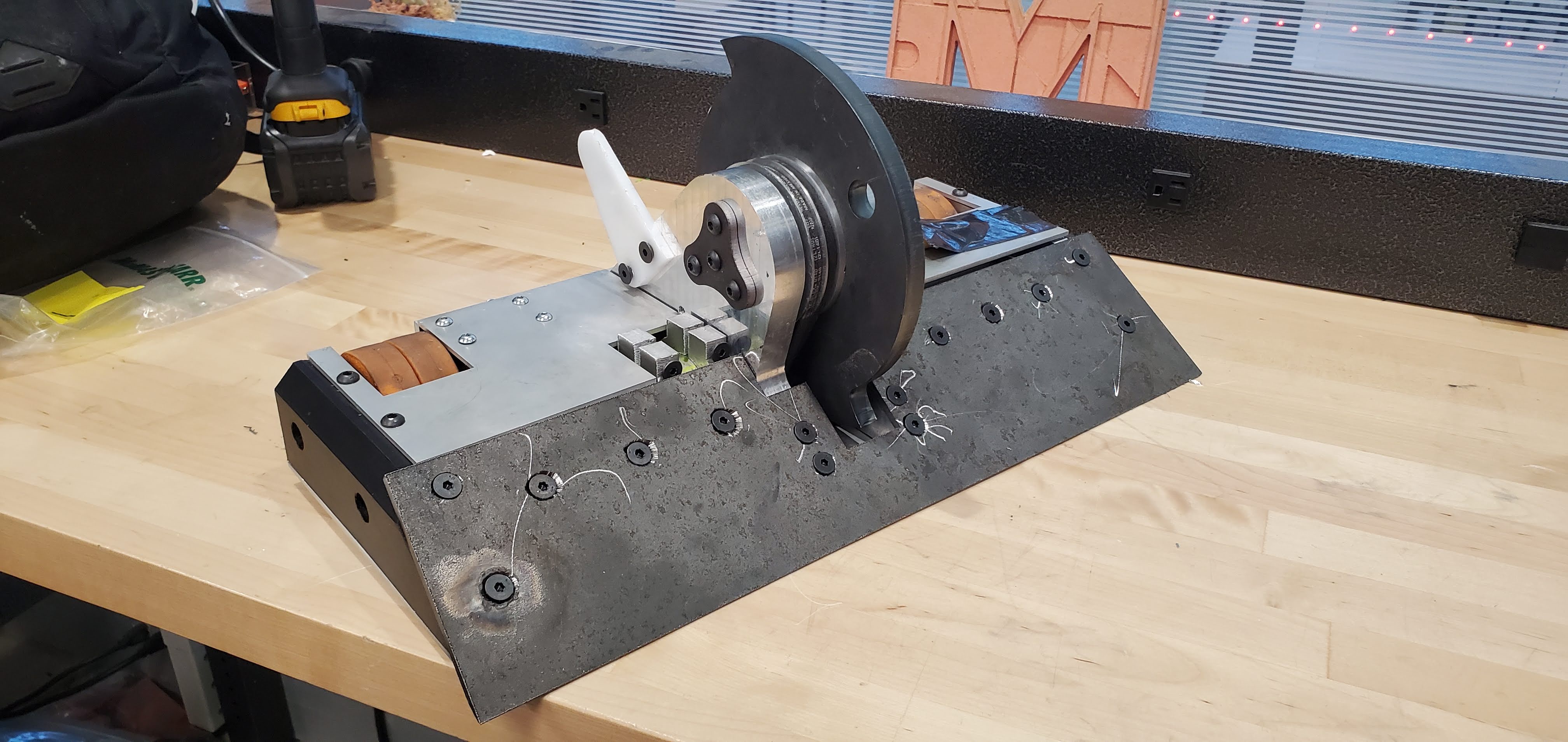

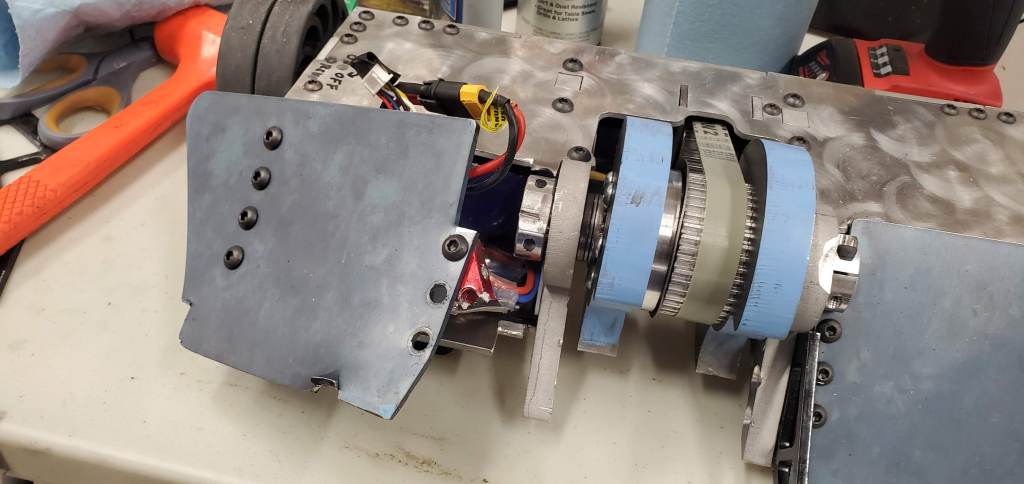

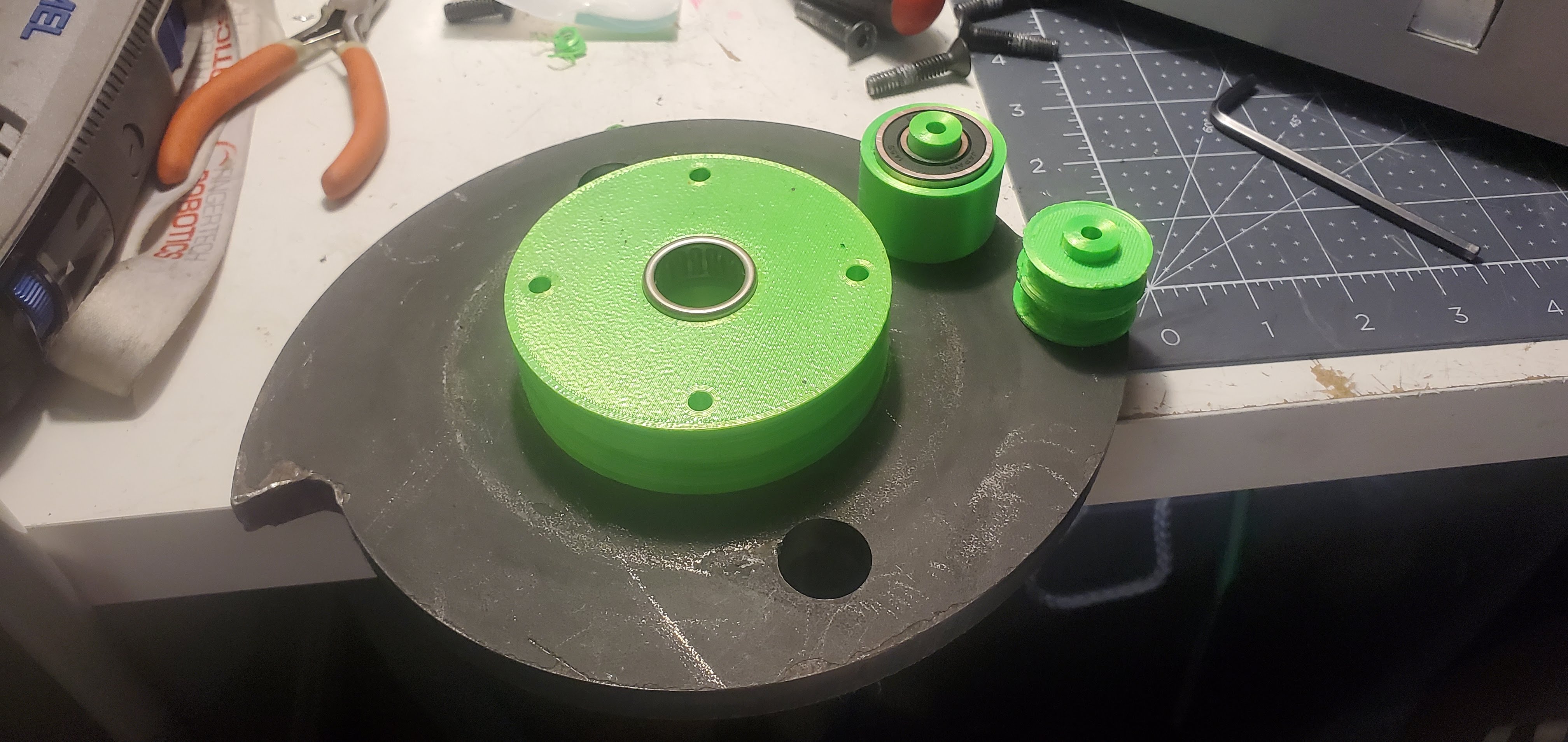

Once again utilizing the Datron Neo, the center frame rails were machined from 3/4″ UHMW then tapped for 1/4-20 threads. The primary hub was the most complex component on the entire machine. V-belts were selected for power delivery as their shape allowed for good friction to get the blade up to speed, but because there was no interlocking geometry, such as teeth commonly found on chain or timing pulleys, it allowed for slipping during high impacts which allows the motor to keep spinning and not transfer energy to its shaft. The spline feature was included to transfer the force from the blade over a large area thereby resisting bending while still ensuring full energy transfer from the belts. The 4x 1/4-20 screws help some with bending, but are primarily in tension to keep the blade attached to the face of the hub. The hub was manufactured by a combination of Okuma GENOS L200E-M CNC lathe for the grooves and bearing shoulder on one side (all thanks to a friend who could run the machine) then using the Datron Neo to cut the spline pattern and other bearing shoulder into the face. This work culminated in the 1/2″ AR500 blade keying into the hub with only a slightly touch up by a rotary tool to clean up laser kerf required.

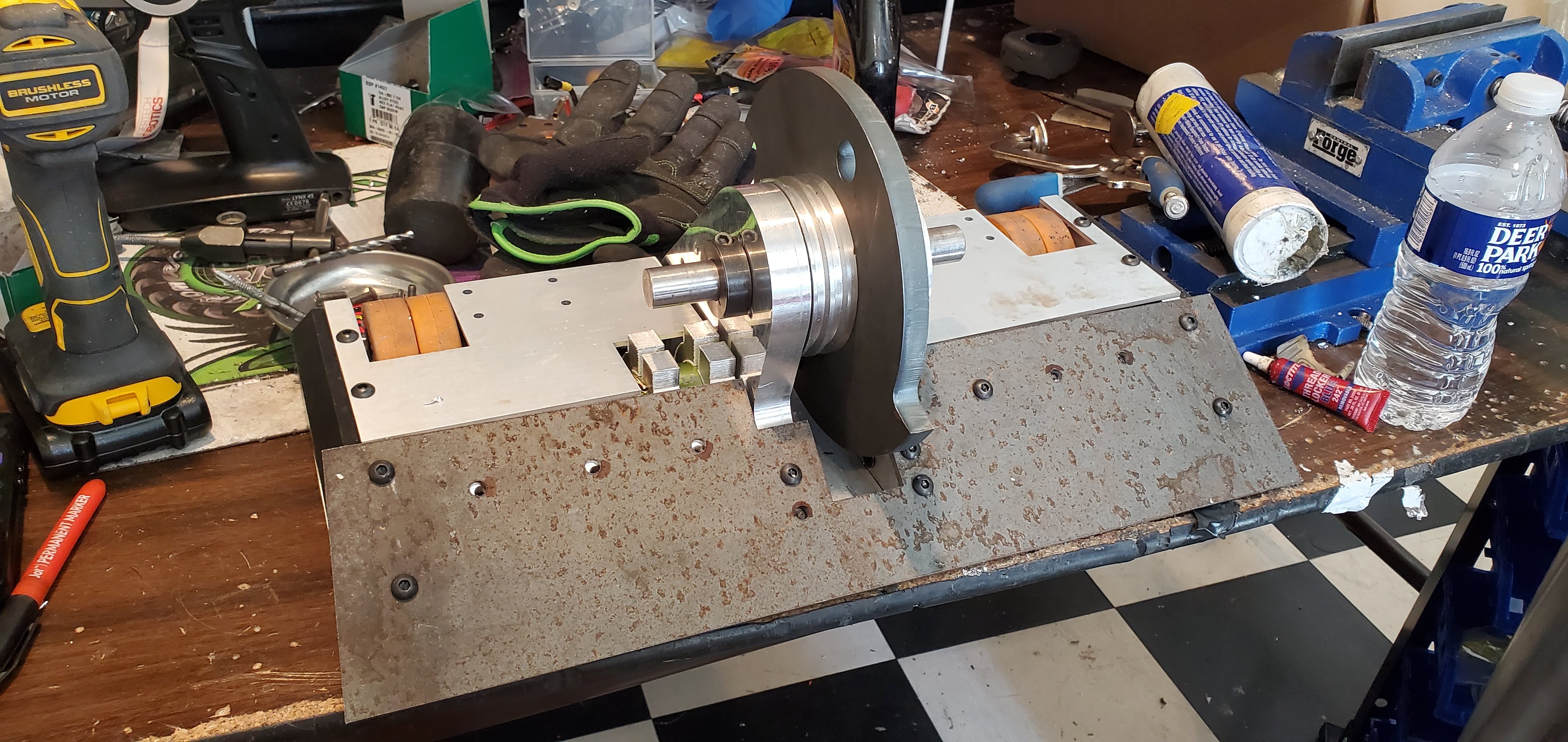

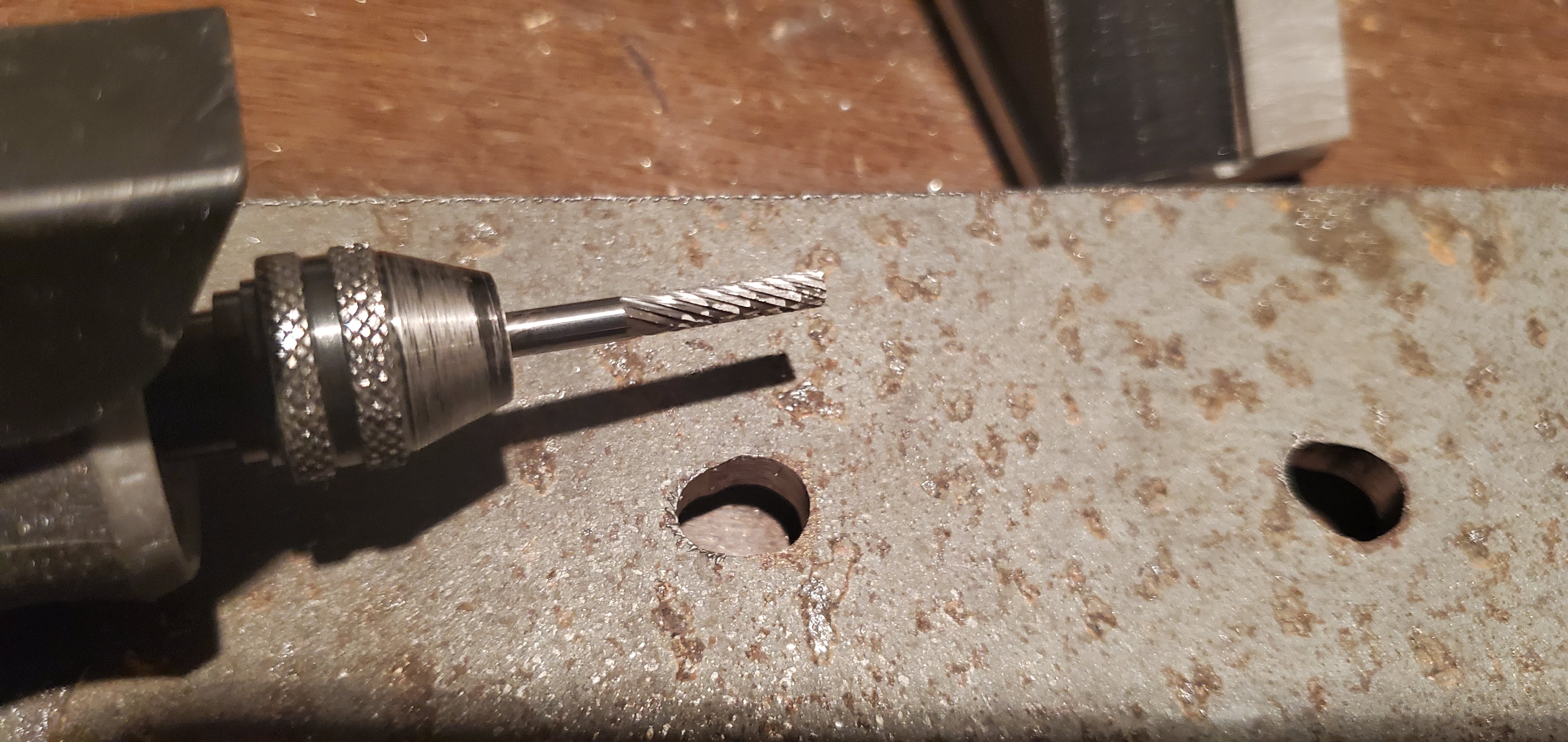

Once these components were machined, the chassis assembly came together very rapidly. Once the 3/4″ needle roller bearings were installed into the hub, case hardened linear rod from McMaster-Carr was acquired. While stronger material such as heat-treated S7 tool steel would be more desirable, the softer material allowed for cutting and tapping on the manual lathe with no heat-treating required. One of the issues that I ran into during assembly was tolerance stackup on components; while some parts directly bolted together, others didn’t and because the holes were already drilled and tapped, the 1/4″ AR500 wedge had to be cut to fit the new holes. Once the area was marked in red, a tungsten bit was used in a rotary tool to grind away the unwanted material. To avoid getting many steel splinters, a vacuum was nearby to suck away the material and all skin was covered up (gloves, long-sleeves, safety glasses, mask, long pants).

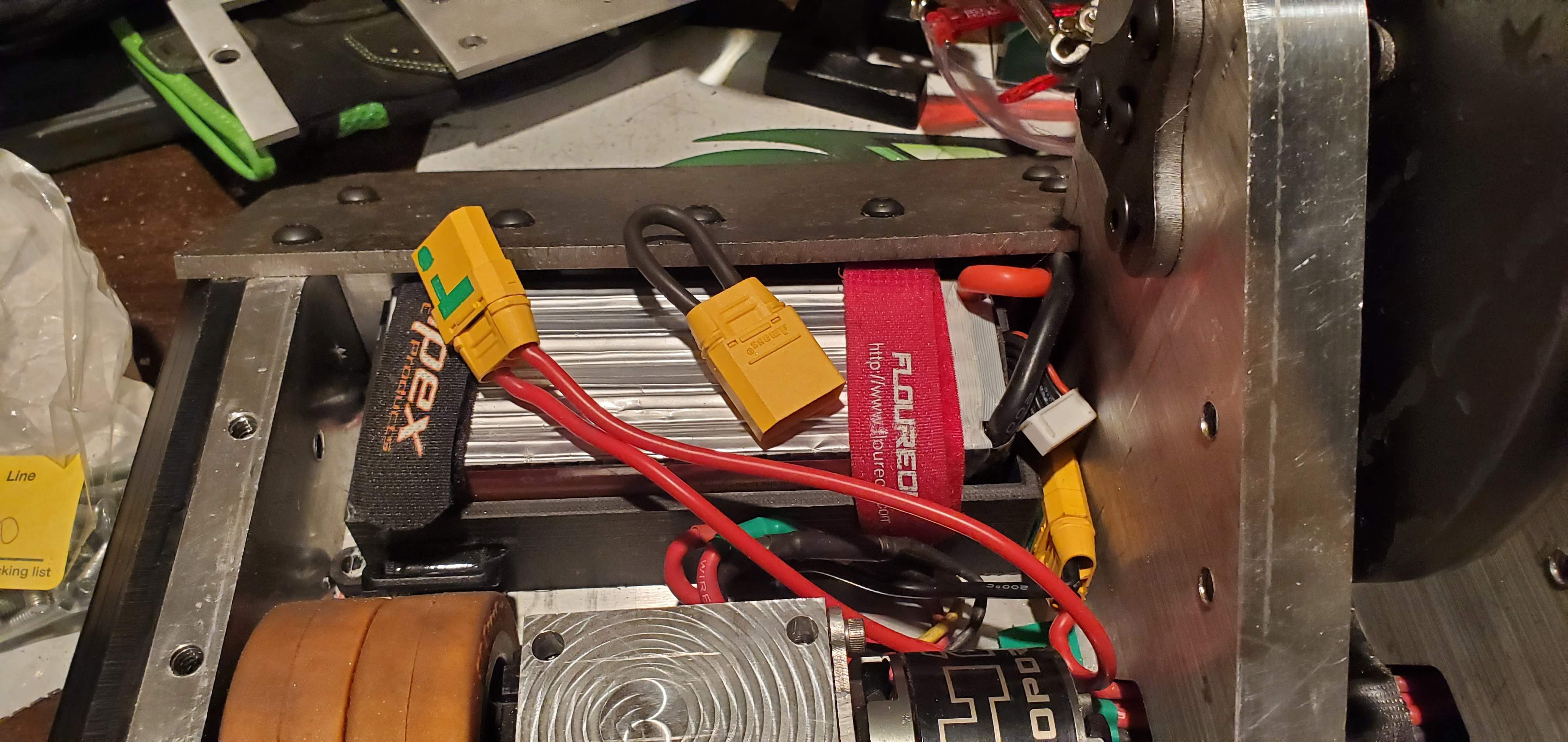

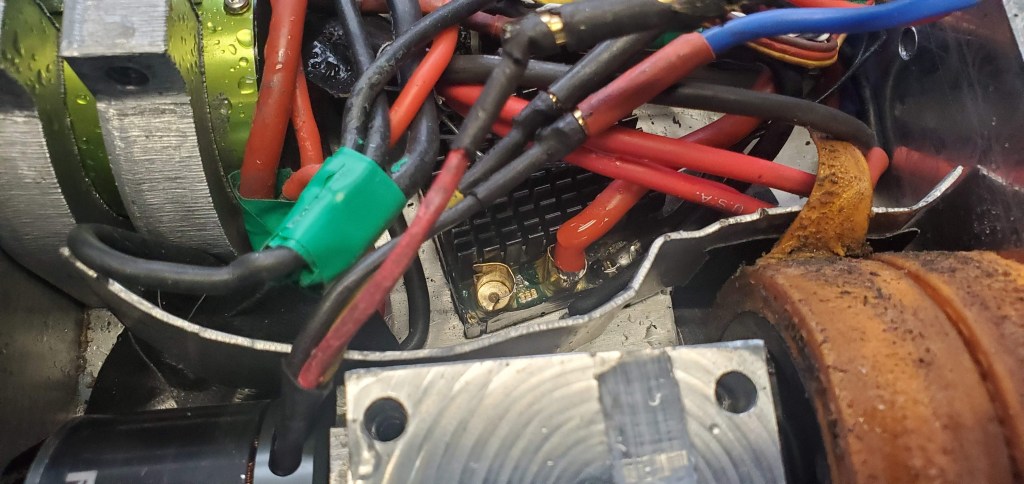

After widening the holes some, all of the aluminum and steel components were connected to each other, forming a superstructure which bolts onto the aluminum baseplate. The electronics were wired and connected via cutouts in the central rails. Most notable for this robot was the use of a removable link method which utilizes a XT90S anti-spark plug which was necessary given the use of 5000mah 6s (24V) Lipo batteries which gave plenty of power and current capacity to fuel the weapon. The batteries and mount were inherited from my lightweight Tactic. After the robot was assembled, it was taken to Terrapin Works where a TIG torch was used to anneal the immediate area around the hole of the AR500 wedge so a normal countersink could be used. This only worked slightly as the welder ran out of Argon so I had to resort to use a Tungsten bit from a local hardware store in a rotary tool mimic a countersink. Much like the hole widening in the previous operation, safety precautions were taken to avoid creating steel splinters from cut material.

After tuning and modifying the parts, the robot had finally come together. Unfortunately, the CAD calculations were off for the weapon pulleys’ center-to-center distance which required them to be modified again by hand. Because this was hours before hitting the road, the process was rushed leading to the pulleys being over-cut which made them too loose instead of too tight. To (hopefully) remedy this, a Teflon bushing was cut and bolted into the frame rail. The position was played with several times to see what can get the belt to be taught in any way. The result wasn’t pretty and practically guaranteed a rough time since the bushing was fixed (no rolling, just rubbing) but it was enough to make sure the motor would turn the blade so it was sent out to its first event.

NHRL March 2021

To its credit, Phenomenon qualified in its first time out at NHRL with a 3rd place finish and delivered some of the best hits of the tournament with its fights against SMEH and all-time best fights in 30lbs against Stop Hitting Yourself. It sustained very little lasting damage except for this shot from SHY which bent the left side permanently. It still drove, but it never laid flat again. Also, the quick tension solution did not work very well for very long, resulting in the robot spewing smoke from the friction of the V-belt rubbing against the fixed tensioner. This system clearly needed improving, but it was clear that while it worked it was potent so figuring that out will be the main progress going forward!

After the event, plans turned to prepare for the Finals in December. Phenomenon mainly rested until December with focus shifting the rest of the year to the smaller weight classes. After other events of the year passed (including Battlebots 2021) the chassis was stripped down and looked over. Clearly the shot from SHY left its mark as the rail was indeed bent. New hardware was swapped in to eliminate some source of bending, but the baseplate was tricky to work out. Ultimately a second set of parts to make another chassis began production, once again utilizing the Datron Neo and 3D-printed jigs to connect the frame rails together. Unfortunately a 1/4-20 tap broke off in the rails and had to remain after unsuccessful attempts to extract it. All in all, progress continued to move forward and the new chassis was stored for spares for the Finals. To help troubleshoot the blade problems, 3D-printed stand-ins were made for the pulley and a tensioner with the goal of tackling that pulley problem. A fork system was also made, though using 6061 as the fork tips due to being close on time and the abundant availability of it at the lab for waterjetting. With that in mind, final parts were made and the bot travelled up north for the NHRL Finals!

NHRL December Finals 2021

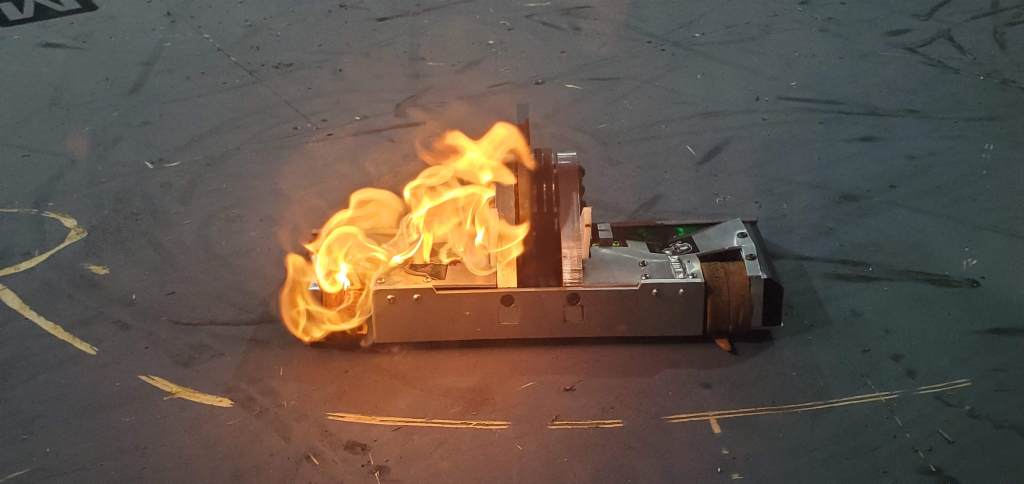

The Finals did not start well for Phenomenon. Due to SMEH not attending, Phenomenon got a bye in the first round and drew MegatRon. This wasn’t made clear until shortly before the fight so I was unable to switch to a fork setup. With the ground game firmly in hand, MegatRon set the lipo battery on fire, leading the crew to quickly remove the robot and bring it outside. It was raining that day so as the battery was consumed, the rest of the robot was being doused in water, not a good idea for a machine with no focus on water sealing.

This began a lifelong fear and determination to defeat MegatRon, the great labor of Phenomenon for as long as it lives.

Upon further inspection, Megatron’s hit did damage the machine, but because the battery is isolated it didn’t harm the electronics. The weapon controllers was damaged some and a section of the Vex Versaplanetary gearbox was struck, but the aluminum pillow block above the drive motor took most of the impact and saved the machine. The rest of the event was less eventful, but the machine accomplished a fair 2-2 finish. Looking at the year, Phenomenon had not yet reached its potential. In its fight against Polyester, the weapon simply never got up to speed which eliminated any chance it had at winning nor did the forks works due to the soft aluminum getting easily chewed by the steel weapons. For 2022, improving the weapon and toughening the forks would be the emphasis.